Demand Planning vs Supply Planning is a very pertinent question among Supply chain enthusiasts. While planning for Inventory for any business, the two core components demand our attention – Demand Planning and Supply Planning. Both of these processes play a pivotal role in ensuring effective and efficient operations, but they often become a source of confusion for those unfamiliar with the industry. In this blog post, we’ll elucidate the similarities, differences, and interdependencies of Demand Planning and Supply Planning, digging deep into the intricate dynamics that drive both of these crucial elements.

Demand Planning vs Supply Planning: Key Areas of Difference

Demand Planning and Supply Planning are two critical components of supply chain management, each focusing on different aspects of ensuring that products are available to meet customer needs. Understanding their key areas of difference is essential for effective supply chain optimization.

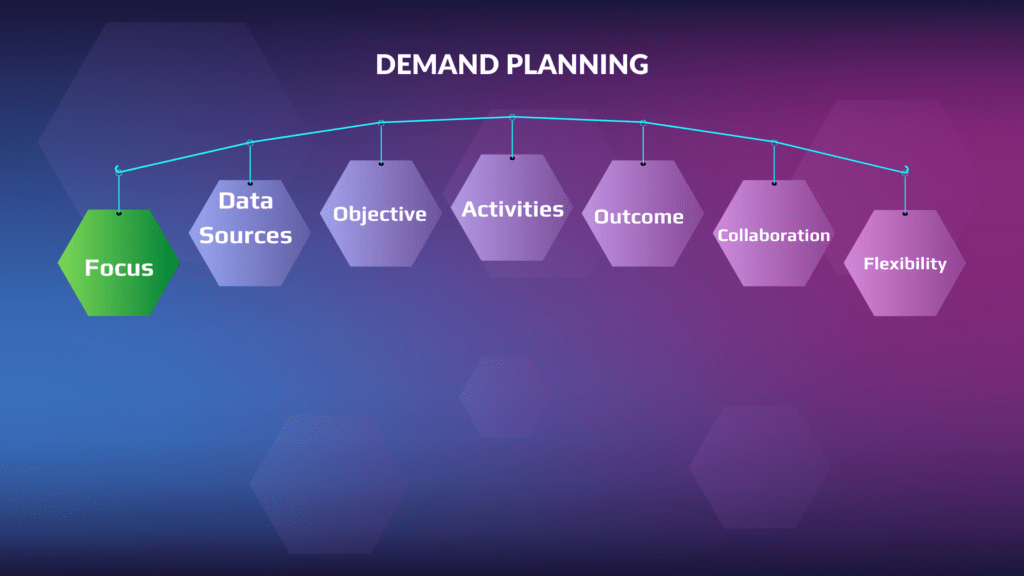

Demand Planning

Focus: Demand Planning primarily concentrates on forecasting customer demand for products. It involves predicting sales to ensure that the company can meet customer expectations without overproducing.

Data Sources: This process uses historical sales data, market trends, seasonal fluctuations, promotional activities, and economic indicators to forecast future demand.

Objective: The main goal is to predict as accurately as possible what customers will want, in what quantities, and when they will want it.

Activities: Includes market analysis, trend forecasting, developing demand scenarios, and creating demand plans.

Outcome: The outcome is a demand forecast that guides the production, procurement, and distribution plans.

Collaboration: Often involves collaboration with marketing, sales, and customer service departments to gather insights and intelligence.

Flexibility: Demand planning must be flexible to adapt to market changes, new product introductions, and unexpected shifts in consumer behavior.

Supply Planning

Focus: Supply Planning is focused on meeting the forecasted demand by efficiently managing the supply of products. It involves ensuring that there is enough inventory to meet demand without incurring excess costs.

Data Sources: Uses the demand plan, inventory levels, supplier lead times, production capacities, and logistics capabilities.

Objective: The goal is to optimize the supply chain to ensure product availability while minimizing costs and maximizing efficiency.

Activities: Includes inventory management, production planning, supplier management, and logistics planning.

Outcome: The outcome is a supply plan that ensures the right products are available in the right quantities, at the right time and place.

Collaboration: Involves close coordination with manufacturing, procurement, logistics, and suppliers.

Efficiency and Cost Control: Focuses on optimizing inventory levels, reducing lead times, and controlling costs.

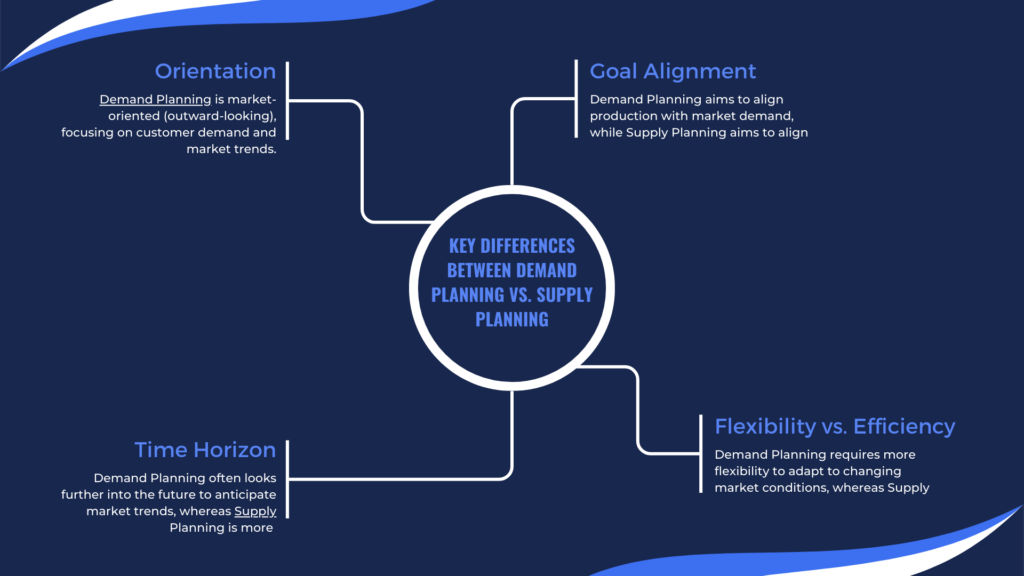

Key Differences Between Demand Planning vs. Supply Planning

Orientation: Demand Planning is market-oriented (outward-looking), focusing on customer demand and market trends. Supply Planning is operationally oriented (inward-looking), focusing on internal processes and capabilities.

Goal Alignment: Demand Planning aims to align production with market demand, while Supply Planning aims to align supply chain processes to meet this demand efficiently.

Time Horizon: Demand Planning often looks further into the future to anticipate market trends, whereas Supply Planning is more concerned with the immediate and medium-term operational aspects.

Flexibility vs. Efficiency: Demand Planning requires more flexibility to adapt to changing market conditions, whereas Supply Planning emphasizes efficiency and cost control within the supply chain.

Demand Planning vs Supply Planning: A Tabulated Overview

| Aspect | Demand Planning | Supply Planning | Real-Life Example |

| Primary Focus | Forecasting customer demand for products | Managing the supply of products to meet forecasted demand | A fashion retailer predicting seasonal trends in clothing |

| Key Objectives | Predict customer needs; Align inventory with market demand | Ensure product availability; Optimize supply chain efficiency | A tech company aligning production with a new product launch |

| Data Sources | Historical sales data, Market trends, Promotional activities, Economic indicators | Demand forecasts, Inventory levels, Supplier lead times, Production capacities | A supermarket using past sales data to forecast holiday demand |

| Main Activities | Market analysis, Trend forecasting, Developing demand scenarios, Creating demand plans | Inventory management, Production planning, Supplier management, Logistics planning | A car manufacturer planning production based on predicted demand for new models |

| Outcome | A demand forecast that guides production and procurement | A supply plan that ensures product availability and efficiency | A consumer electronics company forecasting demand for a new smartphone |

| Collaboration With | Marketing, Sales, Customer service | Manufacturing, Procurement, Logistics, Suppliers | A beverage company working with marketing on a new ad campaign |

| Flexibility | High flexibility to adapt to market changes | Focused on operational efficiency and cost control | A toy manufacturer adjusting to unexpected holiday season demand |

| Time Horizon | Often longer-term, focusing on future market trends | More immediate and medium-term, focusing on operational aspects | A food producer planning for upcoming seasonal produce availability |

| Risk Management | Adjusting plans based on market risks and opportunities | Managing risks related to supply chain disruptions | An electronics retailer managing risks during a global chip shortage |

| Performance Metrics | Forecast accuracy, Service levels, Market responsiveness | Inventory turnover, Order fulfillment rate, Production efficiency | A fashion brand measuring forecast accuracy against actual sales during a new launch |

| Decision Making | Based on market intelligence and customer data | Based on operational capabilities and resource availability | A furniture store deciding on stocking levels based on housing market trends |

| Technology Used | Demand forecasting tools, CRM systems, Market analysis software | ERP systems, Inventory management software, Production planning tools | An online retailer using AI for demand forecasting and inventory management |

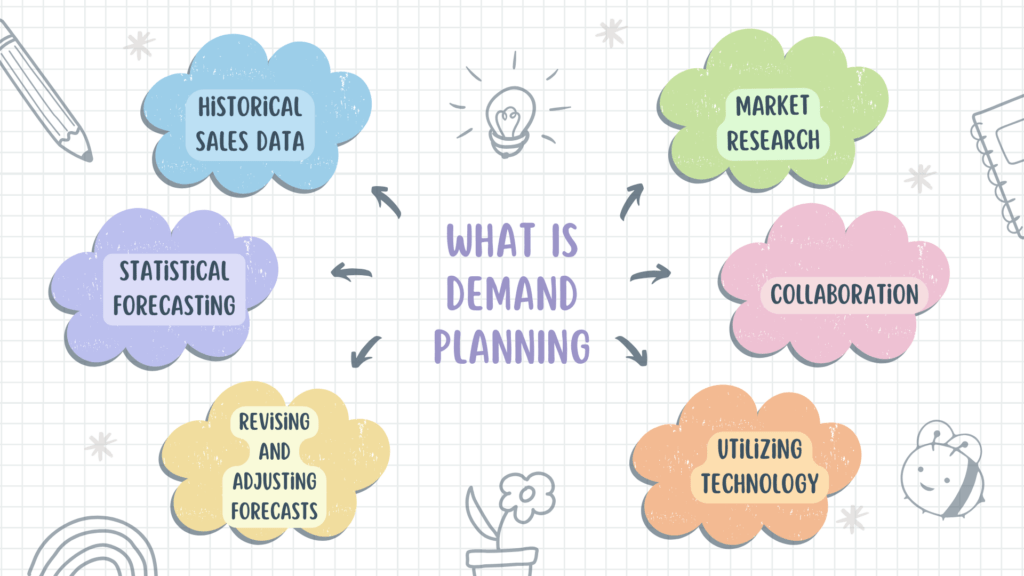

What is Demand Planning

Demand planning, a critical aspect of supply chain management, is a systematic process used by businesses to accurately forecast consumer demand for their products or services. It involves using historical sales data to make informed estimates about future demand, which can help a company plan for potential growth, manage resources efficiently, and reduce costs.

Historical Sales Data

The first step in demand planning is analyzing historical sales data. This can include monthly, quarterly, or yearly sales figures, seasonal trends, and any other relevant information. Companies use software tools and statistical forecasting methods to analyze this data and identify patterns. For example, if a company consistently sells more products during the holiday season, it can plan to increase production and stock in anticipation of this heightened demand.

Market Research

Market research, another crucial part of demand planning, involves analyzing factors that could influence demand for a product or service. These factors might include economic trends, competitor activity, technological advancements, and changes in consumer behavior. For example, if a new competitor enters the market with a similar product, a company might need to adjust its demand forecast accordingly.

Statistical Forecasting

Statistical forecasting involves using mathematical models to predict future demand based on past data. Some commonly used models include linear regression, moving averages, and exponential smoothing. These models take into account trends, seasonality, and randomness in the data. For instance, a company might use exponential smoothing to predict demand if its sales show a stable trend with small, random fluctuations.

Collaboration

Once a preliminary forecast has been created, different departments within the company need to collaborate and provide input. This process is often referred to as collaborative planning, forecasting, and replenishment (CPFR). The sales team might have insights about upcoming promotions that could affect demand, while the production team might have information about potential supply chain disruptions.

Revising and Adjusting Forecasts

No forecast is perfect, and it’s important to continuously revise and adjust forecasts as new data becomes available. This step involves comparing the forecasted demand to the actual demand and making necessary adjustments. For example, if a company underestimated demand for a product, it might need to increase production to meet this higher demand.

Utilizing Technology

Companies often use software tools to manage their demand planning process. These tools can automate data collection and analysis, provide real-time updates, and integrate with other business systems. Some popular demand planning tools include SAP Integrated Business Planning, Oracle Demantra, and JDA Demand Planning.

What is Supply PlanningSupply

Supply planning, a crucial aspect of supply chain management, is the industry process of ensuring that a company has the necessary materials, products, and inventory to meet customer demand. This usually involves coordinating with suppliers, forecasting demand, and determining the appropriate inventory levels to meet projected sales.

Key Elements of Supply Planning

Demand Forecasting

This is a predictive analysis used to estimate the future demand for products. It involves studying past sales data, market trends, and other industry insights. Accurate demand forecasting helps companies plan for the right amount of inventory.

Inventory Management

This involves tracking and managing the goods a company has in stock. The goal is to have a right balance – enough inventory to meet customer demand but not too much to lead to storage cost or product wastage.

Supplier Relationship Management

This involves working closely with suppliers to ensure a steady supply of materials needed for production. It includes negotiating terms and conditions, ensuring quality control, and managing delivery times.

Production Scheduling

This deals with planning when and how much to produce based on projected demand, current inventory levels, and production capacity.

Distribution and Logistics

This involves planning how products will be stored and transported to reach customers. It includes managing warehouses, transportation vehicles, and delivery schedules.

Interrelation Between demand planning vs supply planning

| Aspect | Demand Planning | Supply Planning | Relationship and Integration |

| Primary Focus | Forecasting customer demand | Managing and fulfilling the forecasted demand | Demand Planning forecasts guide Supply Planning actions |

| Objective | Understand future customer needs and market trends | Ensure efficient production and distribution | Supply Planning relies on Demand Planning for accurate production and distribution plans |

| Data Utilization | Uses historical sales, market trends, customer feedback | Uses demand forecasts, inventory levels, supplier capabilities | Demand forecasts are a key input for Supply Planning |

| Role in Supply Chain | Strategic, focusing on what the market will require | Operational, focusing on how to meet these requirements | Demand Planning sets the stage for Supply Planning activities |

| Decision Making | Based on market analysis and predictions | Based on resource allocation and logistics | Supply Planning decisions are influenced by Demand Planning forecasts |

| Outcome | A detailed forecast of customer demand | A plan to meet the demand efficiently | Effective Supply Planning is contingent on accurate Demand Planning |

| Time Horizon | Often longer-term, anticipatory | More immediate and medium-term, responsive | Demand Planning provides a future outlook that Supply Planning must respond to |

| Flexibility vs. Efficiency | Requires adaptability to changing market conditions | Focuses on operational efficiency and cost control | Demand Planning’s adaptability complements Supply Planning’s efficiency focus |

| Example | A retailer predicting holiday season sales | A retailer managing inventory and logistics for the holiday season | The retailer’s Supply Planning is based on its Demand Planning for the holiday season |

Samrat is a Delhi-based MBA from the Indian Institute of Management. He is a Strategy, AI, and Marketing Enthusiast and passionately writes about core and emerging topics in Management studies. Reach out to his LinkedIn for a discussion or follow his Quora Page