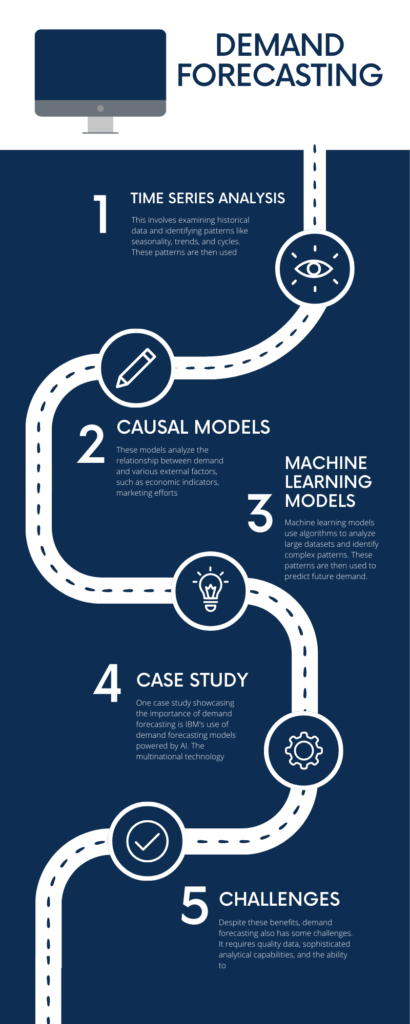

Demand Forecasting

Predicting product demand enables businesses to have the right amount of inventory on hand. Demand forecasting is a key strategy for inventory management as it predicts consumer demand for products or services, allowing businesses to manage inventory more effectively and efficiently.

Demand forecasting uses historical sales data, market research, and statistical methods to predict future demand. The fundamental theories behind demand forecasting include time series analysis, causal models, and machine learning models.

Time Series Analysis

This involves examining historical data and identifying patterns like seasonality, trends, and cycles. These patterns are then used to project future demand.

Causal Models

These models analyze the relationship between demand and various external factors, such as economic indicators, marketing efforts, and price changes.

Machine Learning Models

Machine learning models use algorithms to analyze large datasets and identify complex patterns. These patterns are then used to predict future demand.

Case Study

One case study showcasing the importance of demand forecasting is IBM’s use of demand forecasting models powered by AI. The multinational technology company has been able to achieve a reduction in forecasting errors by up to 28% through their AI-enabled models.

IBM applied machine learning to time-series forecasting, which allowed them to generate short-term and long-term sales forecasts at scale across various product categories. They used different AI models such as Auto-Regressive Integrated Moving Average (ARIMA), Long Short-Term Memory (LSTM), and Decision Trees to make their predictions.

Furthermore, IBM utilized a combination of structured (e.g., sales numbers, stock levels) and unstructured data (e.g., text reviews, social media sentiment) in their forecasting models. By combining different types of data and using machine learning to process it, IBM could create more accurate and sophisticated demand forecasts.

The accuracy of demand forecasting can have a significant impact on business performance. According to a report by the Global Journal of Management and Business Research, a 1% improvement in forecast accuracy can result in a 2% decrease in inventory costs. Thus, demand forecasting can lead to substantial cost savings and increased profitability for businesses.

Challenges

Despite these benefits, demand forecasting also has some challenges. It requires quality data, sophisticated analytical capabilities, and the ability to adjust forecasts based on changing market conditions. Therefore, businesses need to invest in technology, data management, and analytics capabilities to leverage demand forecasting effectively.

Safety Stock

Having a safety stock can mitigate the risk of stockouts. Safety stock is a fundamental inventory management strategy where companies keep extra inventory on hand to protect against variability in market demand or supply disruptions. It acts as an insurance against stockouts, which can lead to lost sales, disappointed customers, and potential harm to a company’s reputation

The theoretical underpinning for safety stock calculations often revolves around lead time, demand variability, and service level expectations. The classic safety stock formula is:

Safety Stock = (Max Lead Time – Average Lead Time) * Average Demand

Here, the Max Lead Time and Average Lead Time represent the longest and average time taken to replenish stock, and the Average Demand is the average units sold during that lead time.

Many companies modify this formula to consider the standard deviation of lead time and demand, as well as the desired service level (probability of not having a stockout).

Implementing safety stock requires a delicate balance. While having a high level of safety stock can prevent stockouts, it also increases inventory holding costs. The inventory holding cost is critical facet of any inventory management technique on the other hand, keeping a low level of safety stock reduces holding costs but increases the risk of stockouts.

Case Study

A case study highlighting the effective use of safety stock is Amazon. The e-commerce giant uses advanced algorithms and machine learning techniques to determine optimal safety stock levels for millions of products. Amazon’s sophisticated inventory management system takes into account various factors, such as historical sales data, product life cycle, seasonal trends, and supplier reliability. This approach has reportedly helped Amazon maintain a high in-stock rate of 97.8% in 2020, reducing the risk of lost sales and improving customer satisfaction.

Moreover, a study by the International Journal of Production Economics found that a well-managed safety stock can lead to a 10-20% reduction in total inventory costs. This is achieved by maintaining a balance between holding costs and the cost of stockouts.

Challenges

Despite its benefits, managing safety stock comes with challenges. It requires accurate data, sophisticated algorithms, and the ability to respond swiftly to changing market conditions. Businesses also need to periodically review and adjust their safety stock levels as demand patterns, lead times, and business goals change.

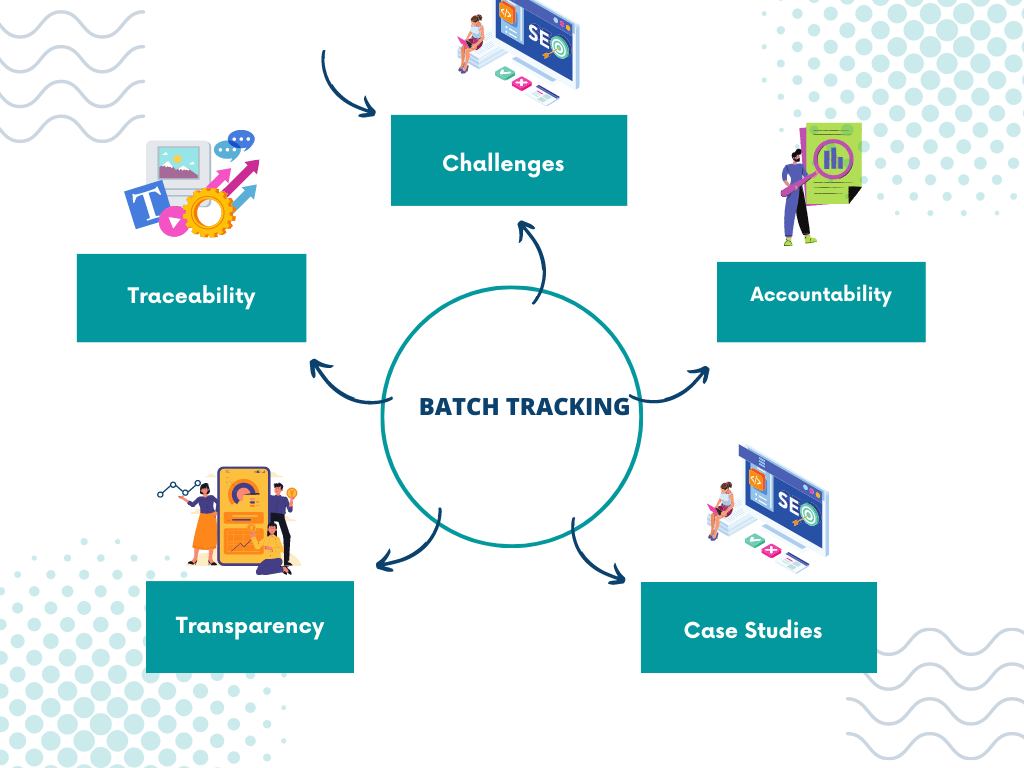

Batch Tracking

Batch tracking can mitigate the risks of product recalls. Batch tracking, also known as lot tracking, is a quality control inventory management technique that allows businesses to track goods along the distribution chain. It is especially important in industries where products need to be closely monitored for reasons of safety, compliance, or quality control, such as food, pharmaceuticals, and electronics.

In essence, batch tracking records the journey of a batch or lot of products or materials from their origin, through the manufacturing process, to the end consumer. This allows companies to manage recalls effectively, ensure regulatory compliance, and improve product quality.

The concept of batch tracking relies on the following principles:

Traceability

Every batch or lot of products should have a unique identifier that allows it to be tracked throughout the supply chain.

Transparency

Information about each batch, such as its origin, processing history, and distribution, should be recorded and readily available.

Accountability

Companies should take responsibility for the quality and safety of their products and have procedures in place for managing recalls or quality issues.

Case Studies

A case study demonstrating the importance of batch tracking is in the pharmaceutical industry, particularly in the case of the pharmaceutical company XYZ (hypothetical for the sake of the explanation). The company implemented batch tracking to improve its inventory management and product quality control. Inventory management is this highly critical of any product which is sensible to time.

The company assigned unique identifiers to each batch of drugs manufactured, enabling it to trace the journey of each batch from the raw materials used, through the manufacturing process, to the distribution to pharmacies. This allowed XYZ to quickly identify and isolate any batches that were associated with quality issues, reducing the scope and cost of recalls.

Furthermore, the implementation of batch tracking led to a decrease in carrying costs by about 27%, as the company was able to manage its inventory more effectively and reduce waste.

Additionally, a study by the Aberdeen Group found that companies using batch tracking had a 26% higher successful product completion rate compared to those not using batch tracking. This demonstrates how batch tracking can contribute to operational efficiency and product quality.

Challenges

However, batch tracking can be challenging to implement. It requires sophisticated tracking systems, accurate data, and strong cooperation from all stakeholders in the supply chain. Therefore, businesses need to invest in the right technologies and processes to implement batch tracking effectively.

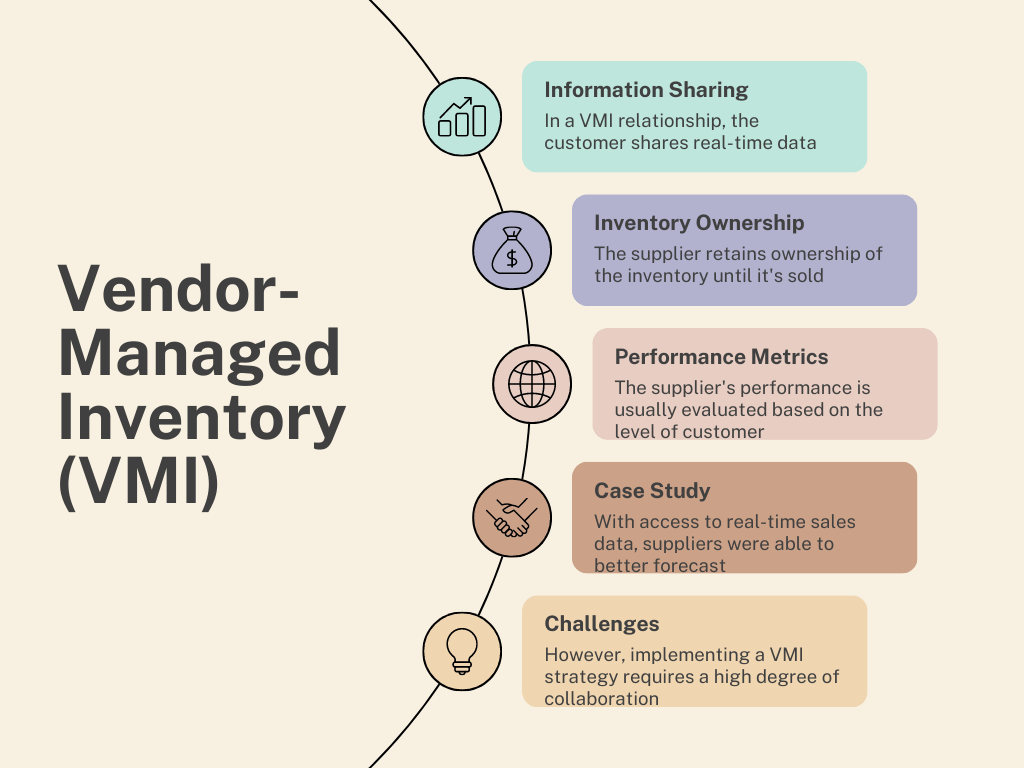

Vendor-Managed Inventory (VMI)

In a VMI arrangement, suppliers manage inventory levels. Vendor-Managed Inventory (VMI) is a supply chain practice where the supplier or vendor is responsible for maintaining the customer’s inventory levels. Under this model, the supplier has access to the customer’s inventory data and is responsible for generating purchase orders.

This practice aims to improve inventory turnover and reduce stockouts or overstock situations. Aligning the manufacturer’s production with the retailer’s sales cycle enhances the efficiency of the supply chain. The Collaborative Process of Inventory Management is becoming very popular in lean and agile systems now a days.

The VMI model is based on several principles:

Information Sharing

In a VMI relationship, the customer shares real-time data on stock levels, sales, and forecasts with the supplier. This transparency allows the supplier to better plan production and deliveries.

Inventory Ownership

The supplier retains ownership of the inventory until it’s sold, effectively transferring the risks associated with inventory management from the customer to the supplier.

Performance Metrics

The supplier’s performance is usually evaluated based on the level of customer service they provide, such as their ability to avoid stockouts and maintain optimal inventory levels.

A successful case study of VMI implementation comes from Barilla, an Italian pasta manufacturer. Before implementing VMI, Barilla suffered from significant demand variability, leading to stockouts and excess inventory. By adopting a VMI strategy, Barilla transferred the responsibility of inventory management to its suppliers.

Case Study

With access to real-time sales data, suppliers were able to better forecast demand, optimize production schedules, and improve delivery performance. This resulted in a 30% reduction in stockout instances and a significant improvement in Barilla’s customer service levels.

The benefits of VMI are supported by numerous studies. According to research by the Journal of Operations Management, VMI can lead to an average inventory reduction of 31% and an increase in service levels by up to 6%.

Challenges

However, implementing a VMI strategy requires a high degree of collaboration and trust between the customer and the supplier. Both parties need to invest in compatible IT systems, adopt standardized processes, and agree on performance metrics. The benefits of VMI also depend on the nature of the products, the stability of demand, and the capabilities of the supplier.

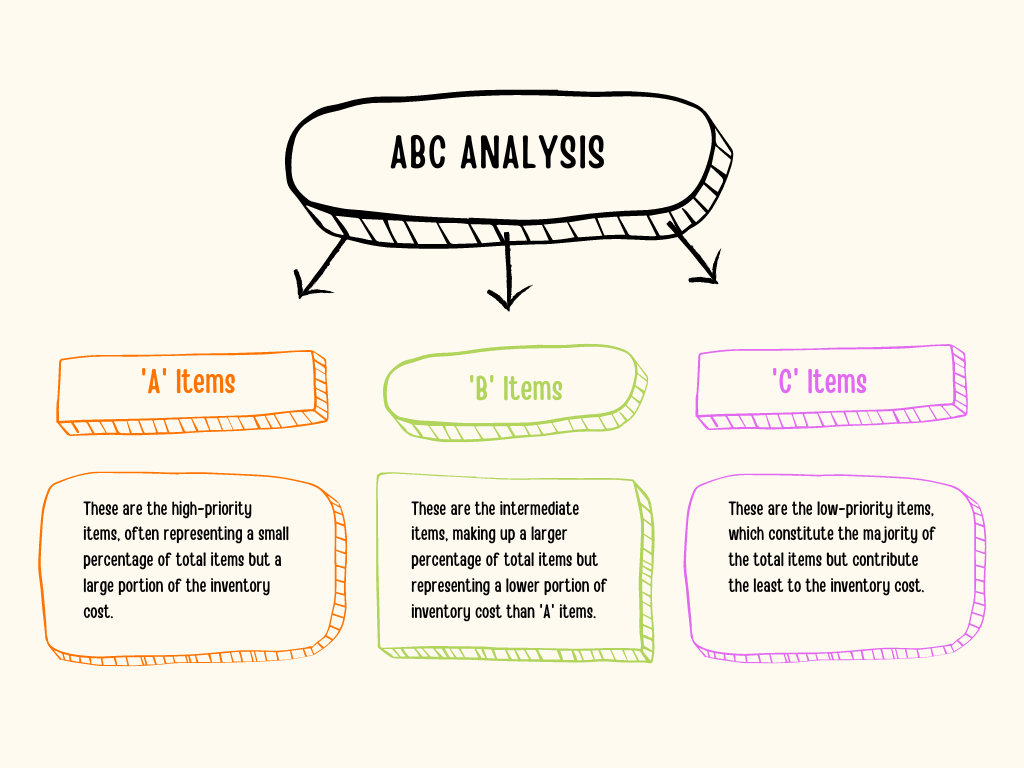

ABC Analysis

This involves categorizing inventory based on its importance and value. ABC analysis is a method of categorizing inventory into three categories based on their importance and value to the business. The system gets its name from the classes it involves: ‘A’ items are very important, ‘B’ items are important, and ‘C’ items are marginally important.

‘A’ Items: These are the high-priority items, often representing a small percentage of total items but a large portion of the inventory cost. They require close inventory control and rigorous demand forecasting.

‘B’ Items: These are the intermediate items, making up a larger percentage of total items but representing a lower portion of inventory cost than ‘A’ items. They require a moderate level of inventory control.

‘C’ Items: These are the low-priority items, which constitute the majority of the total items but contribute the least to the inventory cost. They require less stringent control and can be ordered in larger quantities less frequently.

The basic principle of ABC analysis is the Pareto principle, or the 80/20 rule, which suggests that 80% of the effects come from 20% of the causes. In the context of inventory management, it often happens that 80% of a company’s inventory value is made up of only 20% of its items. The categorization is a basic for any inventory management process

Example and Case Study

An example of the application of ABC analysis is in a pharmaceutical company, XYZ (hypothetical for the sake of the explanation). The company categorized its inventory based on the annual consumption value of each product (calculated as the annual demand multiplied by the cost per unit).

‘A’ items were the top 20% of items that accounted for about 70% of the company’s total inventory value. ‘B’ items were the next 30% of items, contributing around 25% of the total inventory value. The remaining 50% of items, classified as ‘C’ items, contributed only 5% to the inventory value.

By focusing its inventory management efforts on ‘A’ items, XYZ was able to manage its inventory more effectively, leading to a decrease in carrying costs by about 27%.

Several studies have validated the benefits of ABC analysis. For instance, a study published in the Journal of Operations Management found that companies using ABC analysis achieved a 14% reduction in inventory costs compared to those not using it.

Challenges

However, implementing ABC analysis requires a good understanding of the company’s products and market dynamics. It also requires the collection and analysis of accurate demand and cost data. Therefore, companies need to invest in data management and analytical capabilities to apply ABC analysis effectively.

Inventory Turnover Ratio

This measures how often inventory is sold and replaced within a specific period.

The inventory turnover ratio is a key performance indicator that measures the efficiency of inventory management. It represents how many times a company has sold and replaced its inventory during a specific period, usually a year. The ratio provides insights into a company’s operational efficiency, liquidity, and overall financial health.

The formula to calculate the inventory turnover ratio is:

Inventory Turnover Ratio = Cost of Goods Sold (COGS) / Average Inventory

Here,

Cost of Goods Sold (COGS) is the total cost of all goods sold during a specific time period.

Average Inventory is the mean value of inventory during the same time period, usually calculated as the average of the inventory levels at the start and end of the period.

A higher inventory turnover ratio indicates that a company sells its inventory quickly, implying efficient inventory management and high demand for its products. Conversely, a lower ratio could suggest overstocking, slow sales, or obsolete inventory.

Consider a hypothetical example: a retail company, XYZ, which had a COGS of $2 million and an average inventory of $500,000 for the year. By applying the formula, XYZ’s inventory turnover ratio would be 4. This means that XYZ sold and replaced its inventory four times during the year.

The optimal inventory turnover ratio can vary significantly across different industries. For instance, in fast-moving industries like fashion or perishable goods, a high turnover ratio is desirable. In contrast, industries with slower-moving goods, like furniture or appliances, may have a lower turnover ratio. Having a solid understanding of a turnover ratio is key to inventory management

Case Study

According to a study published in the Journal of Business Logistics, companies with higher inventory turnover ratios tend to have higher profit margins. The research found that a 10% increase in the inventory turnover ratio could lead to a 1% increase in the profit margin.

Challenges

However, interpreting the inventory turnover ratio requires caution. While a high turnover ratio can suggest efficiency, it might also indicate inadequate inventory levels, leading to stockouts and lost sales. On the other hand, a low turnover ratio could signal overstocking or weak sales, but it might also reflect a strategic decision to maintain higher inventory levels to guard against supply chain disruptions.

Just-in-Time (JIT) Inventory

This method reduces inventory carrying costs. Just-in-Time (JIT) inventory management is a strategy aimed at reducing in-process inventory and its associated carrying costs. The approach is based on producing goods to meet demand precisely when needed in the production process, not before, thereby minimizing inventory levels.

The underlying principles of JIT are:

Pull System

Production is driven by customer demand rather than forecasts. Each stage of the production process only produces what the next stage needs, and the process starts when the final customer places an order.

Zero Inventory

The aim is to eliminate inventory, both raw materials and finished goods, as much as possible. Inventory is seen as a sign of inefficiency, indicating overproduction and waste.

Continuous Improvement (Kaizen)

JIT is closely associated with the principle of Kaizen, which focuses on continuous improvement in all aspects of the business, including reducing waste, improving efficiency, and enhancing quality.

Case Study

Toyota is famously known for implementing JIT in its production system, known as the Toyota Production System. Before JIT, Toyota, like many other companies, produced more than necessary and stored surplus goods in warehouses, leading to high inventory costs and waste.

Implementing JIT allowed Toyota to dramatically reduce its raw material, work-in-process, and finished goods inventories. By synchronizing the production rate with consumer demand, Toyota reduced its inventory levels by more than 50%, leading to significant cost savings. It also led to an improvement in quality, as it was easier to detect defects in a system with minimal inventory.

Several studies have demonstrated the benefits of JIT. For instance, a study published in the Journal of Operations Management found that implementing JIT can lead to an improvement in return on assets (ROA) by up to 70%.

Challenges

However, successful implementation of JIT requires a stable and reliable supply chain, efficient production processes, and accurate demand forecasting. Any disruption in the supply chain, such as supplier failure or transportation delays, can halt production and lead to stockouts. Thus, while JIT can bring significant cost savings and efficiency improvements, it also comes with its own set of risks.

Real-time Tracking

This involves monitoring inventory in real-time. Real-time tracking in inventory management refers to the continuous and instantaneous tracking of inventory items, from the moment they enter the warehouse until they are sold and dispatched. It involves the use of advanced technologies, such as RFID tags, barcodes, IoT devices, and cloud-based software, to monitor and update inventory levels in real-time. With advanced data analytics, real-time inventory management is becoming more economical.

The primary principles of real-time tracking are:

Instantaneous Updates

Every movement of inventory, from receiving and storing to picking and shipping, is immediately recorded and reflected in the inventory levels.

Visibility

Real-time tracking provides a clear and accurate view of the current inventory levels, location of items, and status of orders at any given time.

Accuracy

By eliminating manual entry and the delay in updating inventory records, real-time tracking significantly improves the accuracy of inventory data.

Case Study

A case in point is Amazon, which uses real-time tracking extensively in its fulfillment centers. Amazon utilizes RFID tags, automated guided vehicles (AGVs), and sophisticated inventory management systems to track each item in its vast warehouses in real time. This allows Amazon to maintain accurate inventory records, streamline order fulfillment, and provide real-time updates to customers.

Implementing real-time tracking resulted in a significant reduction in order fulfillment time, an increase in warehouse efficiency, and improved customer satisfaction due to the visibility into order status. In terms of numbers, Amazon was reportedly able to reduce its “click to ship” time, that is, the time from when a customer places an order to when it’s shipped, from 60-75 minutes to under 15 minutes.

Several studies have shown the benefits of real-time tracking. According to a report by Zebra Technologies, businesses that implemented real-time tracking reported an average improvement of 32% in inventory accuracy and a 27% acceleration in order cycle times.

Challenges

However, implementing real-time tracking requires a significant investment in technology and the development of standardized processes. It also involves a shift in mindset from periodic to continuous inventory management. Therefore, businesses need to carefully assess their needs, capabilities, and resources before implementing real-time tracking.

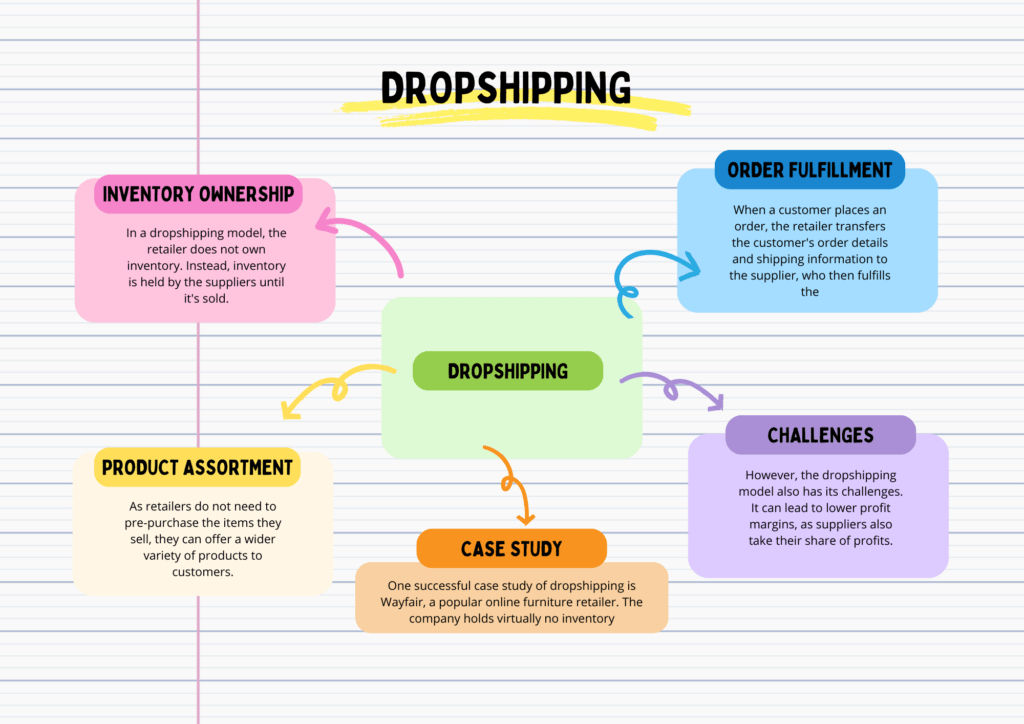

Dropshipping

This involves selling products without stocking them. Dropshipping is a retail fulfillment model in which the retailer does not keep goods in stock. Instead, when a retailer sells a product using the dropshipping model, it purchases the item from a third party—usually a wholesaler or manufacturer—and has it shipped directly to the customer. This eliminates the need for the retailer to handle the product directly, reducing inventory and warehousing requirements. Inventory management with dropshipping needs heavy optimization though.

The fundamental principles of dropshipping are:

Inventory Ownership

In a dropshipping model, the retailer does not own inventory. Instead, inventory is held by the suppliers until it’s sold.

Order Fulfillment

When a customer places an order, the retailer transfers the customer’s order details and shipping information to the supplier, who then fulfills the order directly to the customer.

Product Assortment

As retailers do not need to pre-purchase the items they sell, they can offer a wider variety of products to customers.

Case Study

One successful case study of dropshipping is Wayfair, a popular online furniture retailer. The company holds virtually no inventory and relies extensively on dropshipping. When a customer places an order on Wayfair’s platform, the order is sent to the manufacturer, who ships the item directly to the customer. This model allows Wayfair to offer a vast selection of products without the need to manage complex inventory or large warehouses.

According to data from a report by Market Research Future, the global dropshipping market size was projected to reach approximately $557.9 billion by 2025, growing at a compound annual growth rate (CAGR) of 28.8% from 2018.

Challenges

However, the dropshipping model also has its challenges. It can lead to lower profit margins, as suppliers also take their share of profits. Also, because retailers don’t control the entire supply chain, they can face difficulties with product quality control, order fulfillment, and customer service.

Cross-docking

This involves transferring incoming shipments directly to outgoing trucks, reducing warehouse storage needs.

Cross-docking is a logistics strategy in which products from a supplier or manufacturing plant are distributed directly to customers with minimal to no handling or storage time. The term “cross-docking” comes from the process of receiving products through an inbound dock and then transferring them across the dock to the outbound transportation dock. Cross docking is becoming more popular for large organizations with decentralized inventory management

The core principles of cross-docking include:

Speed

In cross-docking, speed is key. The objective is to unload materials from an incoming semi-trailer truck or rail car and then directly load these materials onto outbound trucks or trailers with little to no storage in between.

Synchronization

The success of cross-docking depends on the synchronization of inbound and outbound transport. The goal is to ensure that the incoming goods arrive just in time to be loaded onto the outbound transport.

Routing

Cross-docking requires a central site where the routing of products is handled. At this site, products are received from multiple sources and then sorted onto outbound trucks going to different destinations.

Case Study

An effective example of cross-docking is Walmart’s distribution model. Walmart’s suppliers send full truckloads of products to a Walmart distribution center, where they’re then distributed to individual stores in less-than-truckload (LTL) quantities. Walmart uses cross-docking efficiently to get products from suppliers to their stores without holding inventory at the distribution centers. It helps them to reduce inventory holding costs, minimize storage requirements, and get products into stores faster, which is crucial in retail industries.

According to a study published in the International Journal of Retail & Distribution Management, the implementation of cross-docking can lead to a reduction in order cycle time by 33%, and inventory reduction by up to 50%.

Challenges

However, to successfully implement cross-docking, companies require significant planning, investment in a central routing facility, and sophisticated logistics software to coordinate and synchronize transport schedules. It’s also crucial to have reliable suppliers that can adhere to strict delivery schedules. If these conditions aren’t met, cross-docking can lead to increased transportation costs, delivery delays, and customer dissatisfaction.

Inventory Management Software

Companies like Oracle, SAP, and Microsoft offer advanced inventory management software that can automate various processes, resulting in reduced errors and increased efficiency.

Inventory management software is a tool that helps businesses track and manage their inventory levels, sales, orders, and deliveries. It can also be used to create purchase orders, back orders, and invoices. The software’s primary purpose is to avoid product overstock and outages, ensuring that the right amount of stock is maintained at all times. Using these software are essential for building a strong inventory management system

The key features of inventory management software include:

Inventory Tracking

This feature allows businesses to track their inventory levels in real time. The software can provide updates when stock is low or when it’s time to reorder.

Barcode Scanning

Many inventory management systems come with barcode scanning capabilities. This allows businesses to quickly input and track products, reducing manual errors.

Reporting and Analytics

These features provide businesses with insights into their inventory levels, sales trends, and order history. This can help businesses make more informed decisions about stock management, pricing, and sales strategies.

Integration Capabilities: Inventory management software can often be integrated with other business systems, such as accounting software, e-commerce platforms, and CRM systems, to streamline operations.

Case Study

One example of a company leveraging inventory management software is Zara, the Spanish clothing retailer. Zara uses sophisticated inventory management software to track each item in real-time, from when it’s manufactured to when it’s sold. This allows Zara to keep track of its fast-moving inventory, respond quickly to changes in demand, and minimize stockouts and overstock.

According to a report by Mordor Intelligence, the global inventory management software market was valued at USD 2.42 billion in 2020 and is expected to reach USD 5.6 billion by 2026, growing at a CAGR of 15% during the forecast period (2021-2026).

Challenges

However, implementing inventory management software requires a significant investment in technology and may require staff training. It also requires the collection and analysis of accurate data. Therefore, businesses need to carefully evaluate their needs and resources before deciding to invest in inventory management software.

Consignment Inventory

Here, payment to suppliers is made only when their goods are sold.

Consignment inventory is a business model in which a consignee (retailer) agrees to receive and store products from a consignor (supplier or manufacturer), but the consignor retains ownership of the products until they are sold. Once the product is sold, the consignee pays the consignor for the inventory. It is very similar yet different from dropshipping model of inventory management.

The core principles of consignment inventory include:

Ownership

In a consignment inventory agreement, the consignor retains the ownership of the goods until they are sold. This implies that the consignor bears the financial risk of the inventory until the point of sale.

Payment

The consignee pays for the inventory only after it is sold to the end consumer. The unsold inventory can be returned to the consignor, reducing the financial risk for the consignee.

Inventory Management

Typically, the consignor is responsible for managing the inventory, which includes replenishing stock when levels are low and removing outdated or unsold merchandise.

Case Study

A great example of the consignment model is the relationship between book authors (consignors) and bookstores (consignees). Many bookstores will display books, particularly from unknown or independent authors, on a consignment basis. This allows the bookstore to offer a wide range of titles without the risk of investing in inventory that may not sell.

According to data from Stitch Labs, using a consignment model can increase revenue by consignment model can increase revenue by as much as 20%, as retailers can offer a wider variety of products without the risk of unsold inventory.

Challenges

However, there are potential downsides to the consignment model. For consignors, delayed revenue recognition and the risk of not selling the inventory can be significant. For consignees, consignment inventory can take up valuable retail space without providing immediate revenue. Also, managing consignment inventory can be complex, requiring careful tracking and accounting to ensure accurate payment upon sale.

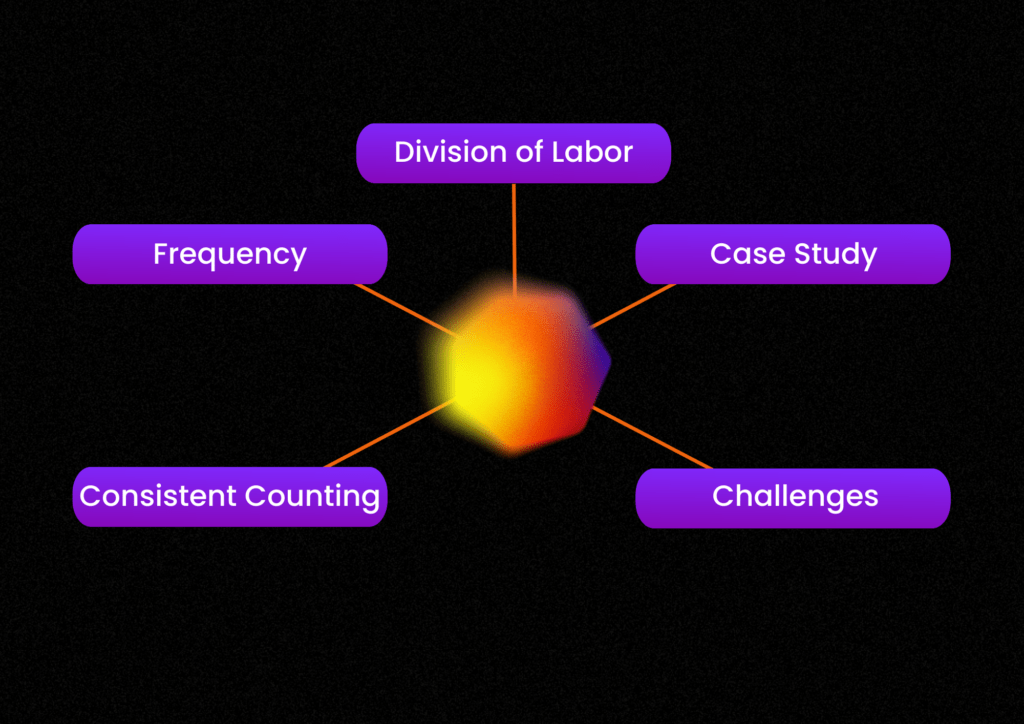

Cycle Counting

This involves regularly counting a subset of inventory.

Cycle counting is an inventory auditing technique where a small subset of inventory, in a specific location, is counted on a specified day. It is a method used by businesses to count their inventory continuously and cyclically throughout the year, rather than counting all inventory at once during a full physical inventory count. Cycle counts contrast with traditional physical inventory counts, where operations are halted once or twice a year to count all inventory items. To bring discipline into inventory management this process is necessary.

The essential principles of cycle counting are:

Consistent Counting

In a cycle counting system, a small, specific subset of inventory is counted at regular intervals, ensuring ongoing accuracy.

Frequency

Inventory items are not all counted at the same frequency. High-value items, fast-moving items, or items critical to business operations are often counted more frequently.

Division of Labor

By breaking down the task of inventory counting into smaller parts, the job can be completed without disrupting normal operations.

Case Study

A successful implementation of cycle counting can be found at Apple Inc. Apple uses cycle counting to maintain an accurate inventory record. This technique helps them to identify and correct potential problems early, reducing discrepancies between actual and recorded inventory.

A study by the Association for Supply Chain Management (APICS) found that companies using cycle counting systems could achieve inventory accuracy levels of 97% or higher. This contrasts with a traditional annual physical inventory system, which often results in lower overall accuracy due to a lack of frequent validation.

Challenges

While cycle counting can significantly improve inventory accuracy, its implementation is not without challenges. It requires a consistent and ongoing effort and requires businesses to invest in proper training for staff to conduct the counts effectively and efficiently. If not appropriately managed, cycle counting can lead to discrepancies and errors.

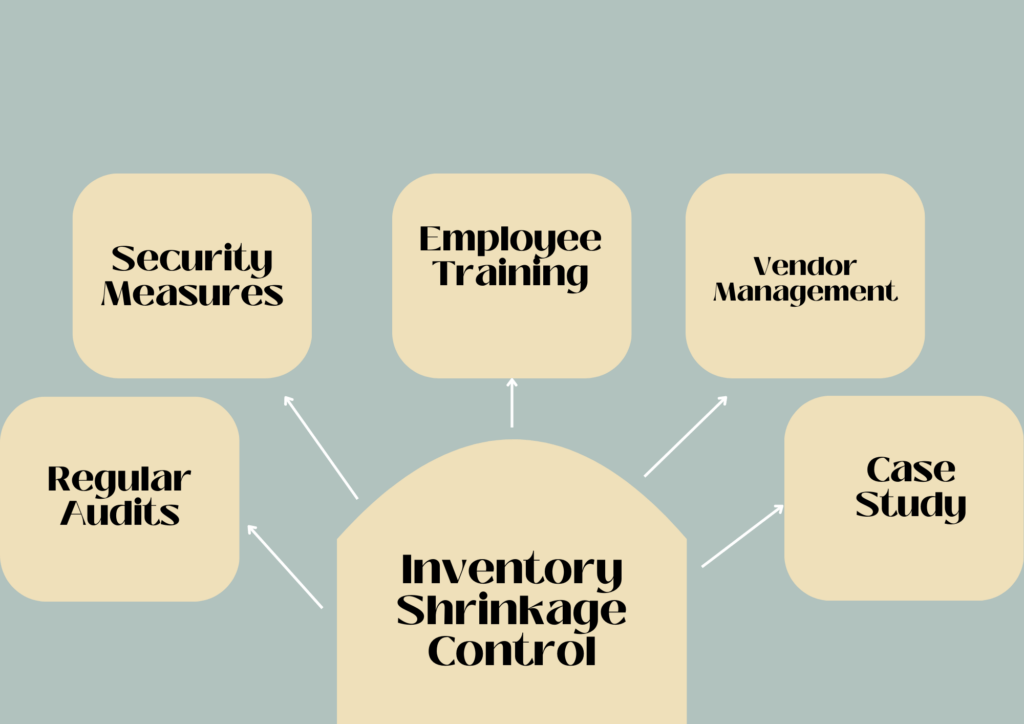

Inventory Shrinkage Control

Implementing measures to control shrinkage can reduce inventory losses. Inventory management thus takes central stage.

Inventory shrinkage refers to the loss of products between the point of manufacture or purchase from suppliers and the point of sale. It is a significant issue that can impact a company’s bottom line. The main causes of inventory shrinkage include theft, damages, miscounting, and supplier fraud. Instilling discipline is required for any type of inventory management.

Here are the key principles to control inventory shrinkage:

Regular Audits

Regular inventory audits, including cycle counting, can help identify shrinkage early and mitigate its impact. It allows you to identify discrepancies between your physical inventory and your inventory records, indicating potential shrinkage.

Security Measures

Implementing security measures, such as surveillance cameras, electronic article surveillance (EAS) systems, and security personnel, can deter theft, one of the significant contributors to inventory shrinkage.

Employee Training

Well-trained employees are more likely to handle inventory properly, reducing losses due to damage or miscounting. Also, educating them about the consequences of theft, including job loss and legal action, can deter internal theft.

Vendor Management

Establishing strong relationships with vendors and carefully monitoring their activities can help prevent supplier fraud. This can include checking shipments for accuracy and quality.

Case Study

One successful case study of shrinkage control is at Target Corporation. The company employs advanced analytics to identify patterns in theft and uses electronic surveillance systems throughout their stores. They also have a rigorous vendor vetting process to prevent vendor fraud. These measures have reportedly resulted in a substantial reduction in inventory shrinkage.

According to the National Retail Federation’s 2020 National Retail Security Survey, the average inventory shrink rate in the U.S. retail industry is around 1.62% of sales. This may seem like a small percentage, but given the volume of sales in the retail industry, it can amount to billions of dollars.

Centralized Inventory

Centralizing inventory can reduce costs and improve efficiency.

A centralized inventory management system is a method where a company maintains its entire inventory from one central location or few select locations. Rather than keeping stock in various places such as individual stores or warehouses scattered across different regions, all products are kept in one central warehouse from which they’re distributed to individual sale locations or directly to consumers. Organizations are looking forward to centralized inventory management after Covid disruptions.

The core principles of centralized inventory management include:

Central Location

In centralized inventory management, all inventory is managed from one central location. This could be a central warehouse, distribution center, or a fulfillment center.

Streamlined Supply Chain

Centralizing inventory allows for a more streamlined supply chain as all goods come in and go out of the same place. This can make it easier to manage and keep track of inventory.

Consolidated Management

With centralized inventory, inventory management is consolidated. This means that one team (or sometimes one person) can oversee the entire inventory, which can lead to more effective management and decision-making.

Case Study

One notable example of successful centralized inventory management is Amazon. Amazon keeps its inventory in large, strategically located fulfillment centers from where they dispatch products directly to customers. This centralized system allows Amazon to manage and control its inventory effectively and deliver products rapidly.

According to a report from Accenture, centralizing inventory management can lead to a 10% – 20% reduction in inventory carrying costs. It also can help companies enhance customer service and increase sales by ensuring the right products are available at the right time.

Challenges

However, there are potential drawbacks to centralized inventory management. One of the main risks is that if the central warehouse encounters a problem (like a natural disaster or a major system failure), it can disrupt the entire supply chain. Also, centralized inventory may not always provide the speed needed for rapid delivery to distant locations.

Samrat is a Delhi-based MBA from the Indian Institute of Management. He is a Strategy, AI, and Marketing Enthusiast and passionately writes about core and emerging topics in Management studies. Reach out to his LinkedIn for a discussion or follow his Quora Page