The term CPFR (Collaborative planning, forecasting, and replenishment) refers to the business process where two or more trade partners pool their resources to develop strategies for meeting client demand, to boosting availability while lowering inventory, transportation, and logistics costs. CPFR combines knowledge of SCM, Inventory Management, and Demand Forecasting among others for fruitful results for both organizations. Generally, Consumer goods and food and beverage are the industries with the highest level of CPFR involvement.

Collaborative Planning, Forecasting, and Replenishment’s (CPFR) primary goal are to “optimize” the supply chain operation through Collaboration and sharing of information between partners. The involvement of these organizations creates synergy and helps in waste reduction between partners.

Brief Overview of the Model

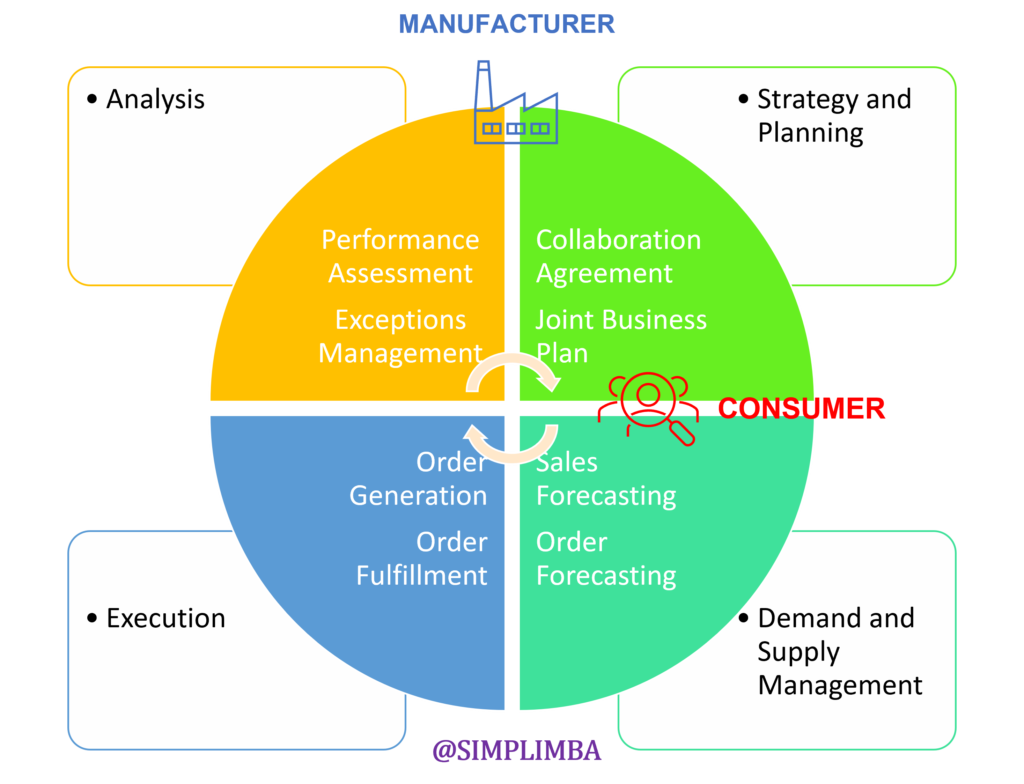

The CPFR model is centered on the client, who generates sales demand for a product. The retailer and its auxiliary services, such as category management, POS forecasting, replenishment management, buying, logistics & distribution, store execution, supplier scorecard, and vendor management, surround the client.

The manufacturer and their operations make up the outer ring of the CPFR model. The model’s four quadrants Strategy & Planning, Demand & Supply Management, Execution, and Analysis are its general organizational structure.

Eight business activities Collaboration Arrangement, Joint Business Plan, Sales Forecasting, Order Planning & Forecasting, Order Generation, Order Fulfillment, Exception Management, and Performance Assessments are used by the retailer, manufacturer, and supply chain partners to communicate.

What are the 4 phases of CPFR in supply chain collaboration?

When it comes to supply chain operations, CPFR, there are four essential components. The following is a succinct description of them:

Strategy and Planning

The plan for cooperative interactions amongst supply chain partners is laid out at this phase. All organizations taking part in partnerships are supposed to have established parameters for their cooperation as well as similar commercial objectives. The strategy and planning phase also outlines roles, duties, and processes.

Demand and Supply Management

The planning of orders and the forecasting of sales are the main topics of this section.

Execution

This stage focuses on the procedures for creating, stocking, sending out, and delivering materials to final consumers.

Analysis

This component includes an evaluation of the performance of the supply chain as well as the handling of exceptions during the fulfillment process.

9 Steps of the cPFR process model

- There are nine steps of Collaborative Planning, Forecasting, and Replenishment (CPFR) :

- Develop Front End Agreement

- Create the Joint Business Plan

- Create the Sales Forecast

- Identify Exceptions for Sales Forecast

- Resolve/Collaborate on Exception Items

- Create Order Forecast

- Identify Exceptions for Order Forecast

- Resolve/Collaborate on Exception Items

- Order Generation

Develop an agreement between supply chain partners. It’s crucial to establish the terms of CPFR collaboration right away. How retailers, suppliers, and manufacturers will improve communication and codify any existing procedures and processes must be agreed upon.

Create one business plan. The business strategy has to be created and approved right away. This guarantees that everyone involved in the supply chain has the same objective of the firm’s success. This is neither a “wish list” of objectives nor a mission statement. The business strategy must include detailed information on both order data and the organizational management of the partners.

Forecast the sales. Sales are now anticipated using the business strategy developed in Step 2. When projecting sales, take into consideration production and inventory planning.

Identify exceptions/deviations in the sales forecast. Now is the time to examine different projections that were created at various supply chain phases. Search for noteworthy deviations or exceptions. This will enable the early detection of any variations.

Resolve exceptions/deviations in the sales forecast. Inform the impacted and accountable partners as soon as possible of any exceptions or deviations. After the exceptions and deviations have been explained, modify the sales projection.

Create the order forecast. Based on the sales data, retailers and suppliers create an order prediction. This is dependent on the company plan’s structural requirements.

Identify exceptions/deviations in the order forecast. This is comparable to what was done in Step 4. Analysis of exceptions or variations from various order estimates made by retailers and suppliers is conducted.

Resolve exceptions/deviations in the order forecast. This is comparable to what was done in Step 5. The order prediction communicates, updates, and renews any exceptions and deviations.

Generate the orders. Once the final order prediction is received, the products are ordered.

What is CPFR used for?

Organizations that have used CPFR in their SCM have reported the following benefits:

- Improving the accuracy of forecasting demand,

- Delivering the right product at the right time to the right location,

- Reducing inventory,

- Avoiding stockouts, and

- Improving customer service.

However, having cooperative trade partners that share risk and information throughout the process is the most crucial factor that determines if the CPFR’s objectives and operations will be successful. The supply chain will be “suboptimal” as a result of cooperative planning and forecasting amongst the trade partners, yielding earnings that are less than maximum. It has been shown that forecasts created only by businesses are frequently erroneous, therefore in the CPFR system, when the buyer and seller agree on forecasts, it is feasible to match customer demands with supplier production schedules, resulting in competent replenishment. Additionally, CPFR aids in avoiding expensive post-event modifications when demand or promotions shift.

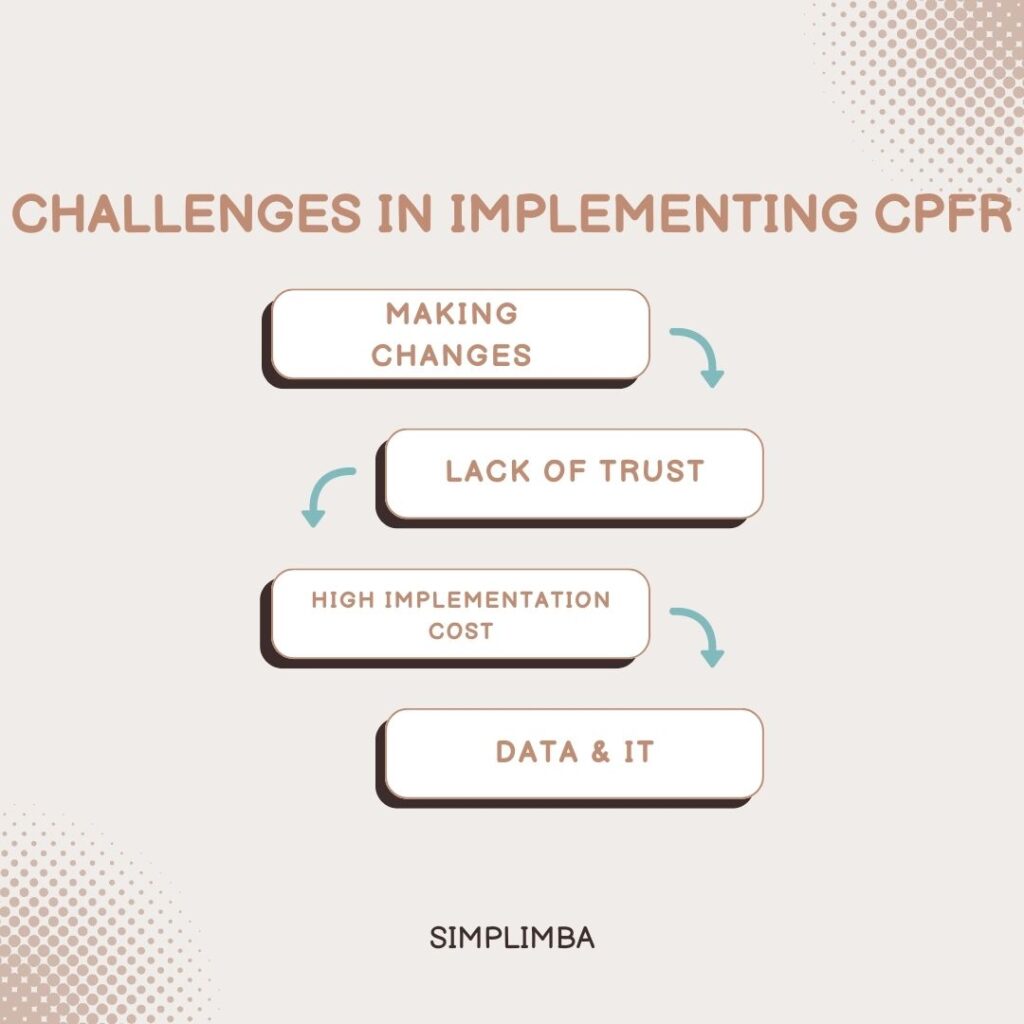

Challenges for CPFR implementation

The top three challenges that organizations encounter while implementing CPFR are as follows:

Making internal changes: Internal changes must always be handled by top management since change is never easy. However, if top management is committed to the project and educates staff about the advantages of CPFR, there is a greater likelihood that an internal change will be effective.

The total cost of implementation: While price should always be taken into account, businesses must also assess if doing so would put them at a competitive disadvantage.

Trust: One of the main barriers to CPFR’s widespread deployment is a lack of retailer willingness to disclose the data needed to do so.

Data: The whole model is dependent on generating and utilizing data. Many smaller organizations do not have the technical capability to generate and interpret such a huge volume of data

Lack of IT Systems: Many smaller organizations do not have the IT Systems to generate real-time ordering and inventory management processes which may make the CPFR model unsuitable

CPFR in the Supply Chain Management

Collaborative planning, forecasting, and replenishment, or CPFR, is a technique created to lower supply chain costs by fostering cooperation among several potential partners in a single supply chain.

Origins of CPFR in Supply Chain

CPFR is not only a fancy moniker for a hazy or fuzzy idea. The Voluntary Interindustry Commerce Solutions (VICS) Association, which established a framework and set of instructions for performing CPFR in supply chains, really developed it. It came to know as VICS CPFR model

Since its introduction, some organizations have implemented CPFR warily while others have done so more fervently. For instance, the world’s largest manufacturer of appliances, Whirlpool, embraced CPFR for its supply chain and had great success. Whirlpool struggled with a prediction error rate of 70% before the adoption of CPFR, which fell to 11% when the firm and its supply chain partners started cooperating under the CPFR framework.

How can CFPR help in the reduction of wastage in supply chain management?

CFPR help in the reduction of wastage in supply chain management in 8 ways

- Start at the end, with the customer

- Review production lines and administrative processes for unnecessary procedures and rework

- Map communication channels to highlight breakdowns

- Review equipment and delivery policies

- Bring in suppliers and industry experts for a fresh perspective

- Review returns policy and handling

- Set up feedback loops and return for regular reviews

- 8 Establish reports and tolerance levels to monitor future waste

The benefits of CPFR

- Ties with supply chain partners are strengthened.

- provides sales and order forecast analysis, which raises the forecast’s accuracy.

- Control the supply chain and proactively solve issues before they arise.

- Collaboration on upcoming needs and goals is encouraged.

- Combine the functions of forecasting, planning, and logistics.

- Effective category management and comprehension of customer buying trends.

How did Walmart benefit from the CPFR Model?

Walmart co-led the development of the CPFR concept in 1995. Soon after, the business started testing the idea with a few chosen suppliers in Walmart Stores. The CPFR model was having a beneficial effect on shop stock as early as 1997. Listerine was one product that had the highest improvement. The in-stock average for Listerine increased from 87% to 98% with the implementation of CPFR.

Walmart continues to apply the fundamentals and openness of CPFR with its suppliers. The business provides suppliers with access to a single forecast figure so they may comment on other variables affecting the number and suggest changes.

Conclusion

CPFR principles were developed several years ago to solve significant business shortcomings and inefficiencies between producers and retailers. CPFR has advanced to the point where it is now a widely recognized method for improving interactions and business operations amongst these trade partners. The main goal of CPFR is to change the business mindset from one of internal emphasis to one of multi-enterprise knowledge and information exchange.

The advantages that people who use the CPFR model experience demonstrate the worth of a collaborative planning paradigm. Making the shift to a collaborative culture based on trust is one of the biggest obstacles to CPFR implementation for the majority of businesses. The organizations that successfully vault the “four walls” that perpetuate segregated methods, and establish collaborative operational agreements with important trading partners, rapidly discover that confidence increases swiftly

FAQs

What is CPFR used for?

Improving the accuracy of forecasting demand,

Delivering the right product at the right time to the right location,

Reducing inventory,

Avoiding stockouts, and

Improving customer service.

What are the 4 phases of CPFR in supply chain collaboration?

Strategy and Planning

Demand and Supply Management

Execution

Analysis

What are the Nine steps of CPFR?

Develop Front End Agreement

Create the Joint Business Plan

Create the Sales Forecast

Identify Exceptions for Sales Forecast

Resolve/Collaborate on Exception Items

Create Order Forecast

Identify Exceptions for Order Forecast

Resolve/Collaborate on Exception Items

Order Generation

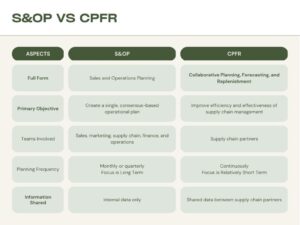

What is the difference between S&OP and CPFR?

Sales and Operations Planning commonly referred to as S&OP, is a cross-functional business process that helps align sales and operations planning. The primary objective of S&OP is to create a single, consensus-based operational plan for the entire organization. This planning process involves multiple teams, including sales, marketing, supply chain, finance, and operations. S&OP is a long-term planning process that is typically done on a monthly or quarterly basis.

Collaborative Planning, Forecasting, and Replenishment, commonly referred to as CPFR, is a collaborative business process that helps improve the efficiency and effectiveness of supply chain management. CPFR involves the sharing of information between supply chain partners to create a single, shared plan for demand forecasting, inventory management, and replenishment. The primary objective of CPFR is to create a more accurate forecast of customer demand, reduce inventory costs, and improve supply chain efficiency.

What are the benefits of CPFR?

Ties with supply chain partners are strengthened.

provides sales and order forecast analysis, which raises the forecast’s accuracy.

Control the supply chain and proactively solve issues before they arise.

Collaboration on upcoming needs and goals is encouraged.

Combine the functions of forecasting, planning, and logistics.

Effective category management and comprehension of customer buying trends

Samrat is a Delhi-based MBA from the Indian Institute of Management. He is a Strategy, AI, and Marketing Enthusiast and passionately writes about core and emerging topics in Management studies. Reach out to his LinkedIn for a discussion or follow his Quora Page