Supply base management refers to the process of effectively managing and optimizing relationships with suppliers in order to ensure a smooth and efficient supply chain. It plays a crucial role in today’s business environment, where organizations are increasingly reliant on global supply chains and face growing challenges in terms of cost, quality, and sustainability.

Advantages of Supply Base Management

Improved Cost and Quality Control

Supply base management enables organizations to carefully select suppliers based on their pricing and quality capabilities. By developing long-term relationships with these suppliers, organizations can negotiate better pricing terms and ensure consistent product quality. For example, in a study conducted by the Aberdeen Group, companies that implemented supply base management strategies were able to achieve a 15% reduction in their direct material costs.

Enhanced Supplier Collaboration:

Effective supply base management fosters collaboration and communication between organizations and their suppliers. This allows for better alignment of goals and objectives, resulting in improved overall supply chain performance. For instance, a case study on Toyota reveals that the company’s close collaboration with its suppliers enabled them to reduce lead times, minimize inventory levels, and improve product quality.

Mitigation of Supply Chain Risks

Supply base management helps organizations mitigate potential risks in their supply chains through proactive measures such as dual sourcing, supplier diversification, and supplier performance monitoring. By having a robust supplier management system in place, organizations can respond effectively to disruptions such as natural disasters, geopolitical tensions, or supplier bankruptcies. A report by Deloitte highlights that companies with strong supply base management had shorter supply chain disruption resolution times compared to their peers.

Sustainability and Ethical Practices

With increasing consumer demand for sustainable and ethically sourced products, supply base management becomes crucial in ensuring compliance with environmental and social standards. By assessing and monitoring suppliers’ sustainability practices, organizations can mitigate their environmental impact, address labor issues, and demonstrate their commitment to responsible sourcing. A study published in the Journal of Operations Management found that organizations that engage in sustainable supply base management observed improved supply chain resilience, innovation, and market performance.

Competitive Advantage and Innovation

Effective supply base management can provide organizations with a competitive advantage by fostering innovation and enabling quicker time to market. By collaborating closely with suppliers, organizations can tap into their expertise and leverage their capabilities to develop innovative products or solutions. A study by ProcurementIQ found that companies that emphasized supply base management were better able to align their suppliers’ capabilities with their own business strategies, leading to increased innovation and competitive differentiation.

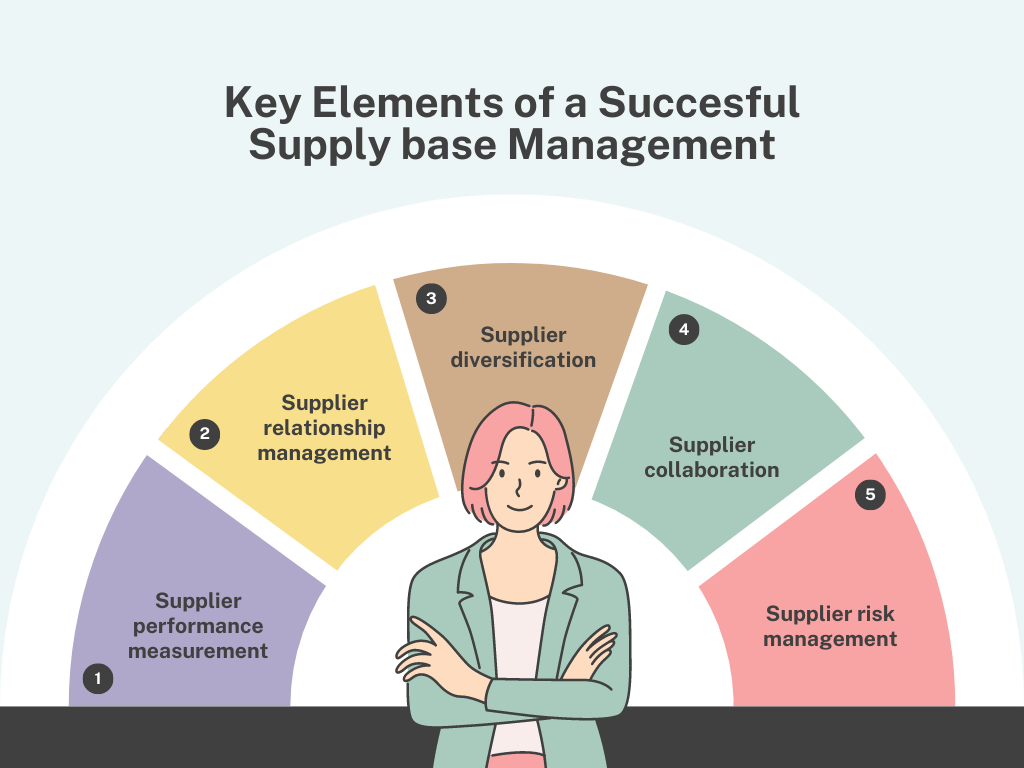

Key Elements of a Succesful Supply Base Management

There are many facets of a successful Supply base Management plan. Not only does Supply base management helps in mitigating risks but it also can drive cost and performance improvements. These are key elements of a successful Supply base Management

1. Supplier performance measurement: One crucial component of supply base management is measuring the performance of suppliers. By collecting data on factors such as delivery times, quality of products, and responsiveness, organizations can identify underperforming suppliers and take necessary actions to improve their performance. According to a study by Aberdeen Group, top-performing companies that effectively measure supplier performance experience a 9% increase in efficiency and a 14% reduction in costs.

2. Supplier relationship management: Building and maintaining strong relationships with suppliers is vital for successful supply base management. By fostering open communication, trust, and collaboration, organizations can ensure that suppliers understand their requirements and can deliver products or services that meet their specifications. For example, Toyota has developed long-term relationships with its suppliers, leading to enhanced quality, efficiency, and innovation in its supply chain.

3. Supplier diversification: Another key component of supply base management is diversifying the supplier base. Relying on a single supplier can increase the risk of disruptions in the supply chain, such as delayed deliveries or quality issues. By having multiple suppliers for critical components, organizations can minimize such risks and ensure continuity in the supply chain. A case study by Harvard Business Review found that companies that diversified their supplier base experienced a 22% reduction in supply disruptions compared to companies with a single-source supplier strategy.

4. Supplier collaboration: Collaboration plays a crucial role in effective supply base management. By involving suppliers in the R&D process or sharing information about demand forecasts, organizations can improve product quality, reduce lead times, and lower costs. For instance, Apple collaborates closely with its suppliers to innovate and introduce new products to the market faster, maintaining its competitive edge.

5. Supplier risk management: Assessing and managing risks associated with suppliers is an essential component of supply base management. This includes identifying potential risks, such as financial instability or geopolitical issues, and developing contingency plans to mitigate these risks. According to a study by Deloitte, organizations that proactively manage supplier risks are 33% more likely to outperform their peers in terms of supplier relationship effectiveness and efficiency.

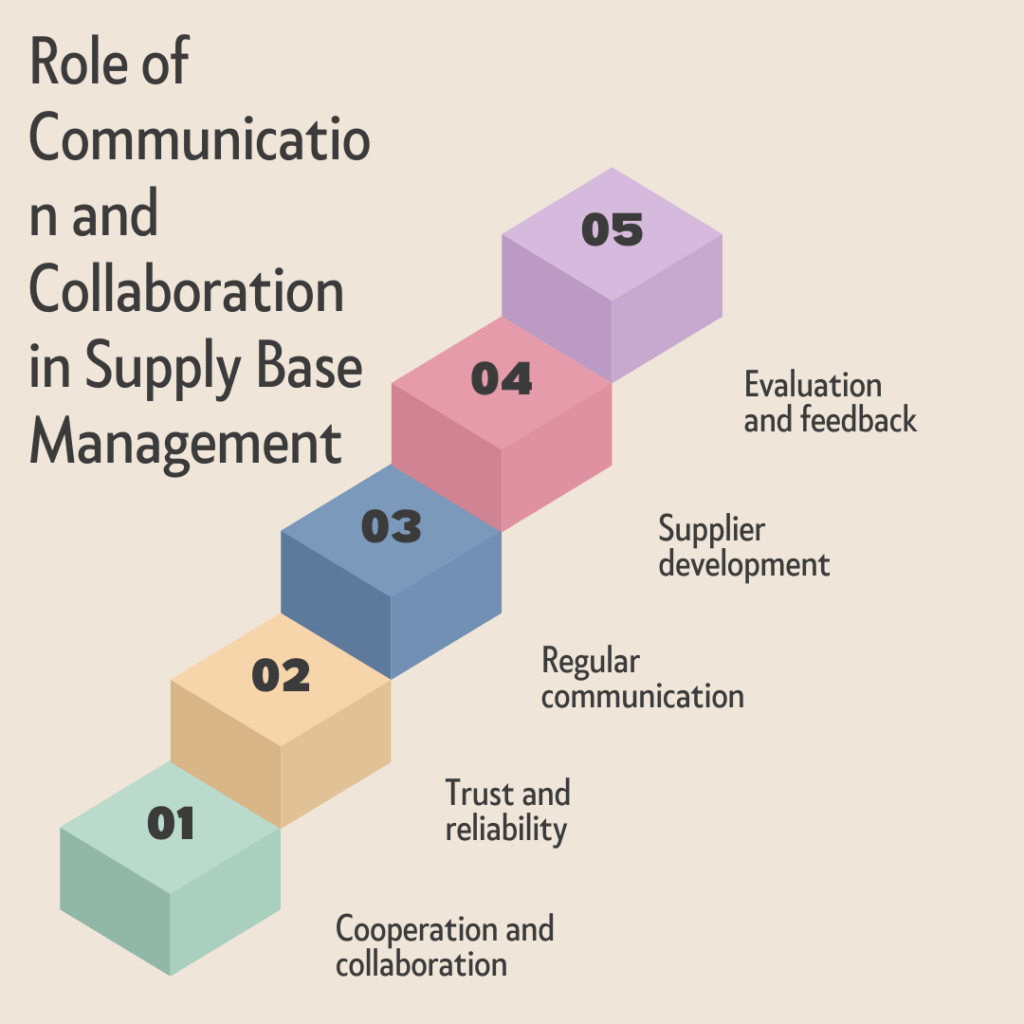

Role of Communication and Collaboration in Supply Base Management

Building and maintaining relationships with suppliers is crucial for businesses to ensure smooth operations, minimize costs, and drive innovation. This is especially important in today’s globalized and competitive market. In this blog post, we will discuss the importance of building strong relationships with suppliers and provide strategies to maintain these relationships effectively.

1. Cooperation and collaboration: Building relationships with suppliers is about more than just signing a contract. It involves creating a sense of cooperation and collaboration. Research has shown that organizations that have a close relationship with their suppliers are more likely to achieve better operational performance and superior product quality. For example, a study by Handfield and Nichols (1999) found that companies that actively collaborate with suppliers have higher levels of customer satisfaction and increased product innovation.

2. Trust and reliability: Trust is the foundation of any successful relationship, and this holds true for supplier relationships as well. Businesses that have a high level of trust with their suppliers are more likely to experience cost savings and improved operational performance. In fact, a survey by Aberdeen Group (2017) found that 60% of companies reported cost savings as a result of improved supplier relationships. Trust is built through consistent and reliable communication, meeting deadlines, and honoring contractual agreements.

3. Regular communication: Communication is essential in any relationship, and supplier relationships are no exception. Regular communication with suppliers helps businesses stay informed about market trends, changes in demand, and potential risks. A study by Lambert and Pohlen (2001) found that companies that have open and frequent communication with suppliers are more likely to achieve higher levels of customer satisfaction and improved product quality.

4. Supplier development: Developing suppliers is another effective strategy for building and maintaining relationships. By working closely with suppliers and providing them with training and support, businesses can help suppliers improve their capabilities, thus leading to better performance and higher-quality products. A case study by Simatupang et al. (2011) found that supplier development programs resulted in improved delivery times, reduced costs, and increased product quality for both the supplier and the buying company.

5. Evaluation and feedback: Regular evaluation and feedback are important for maintaining healthy supplier relationships. By assessing supplier performance and providing constructive feedback, businesses can identify areas for improvement and address any issues or concerns. A study by Fawcett et al. (2008) found that companies that evaluate their suppliers’ performance on a regular basis experience reduced supply chain costs and increased supplier loyalty.

In conclusion, building and maintaining relationships with suppliers is essential for businesses to achieve operational excellence and drive innovation. Cooperation and collaboration, trust and reliability, regular communication, supplier development, and evaluation and feedback are key strategies for maintaining these relationships. By investing in strong supplier relationships, businesses can gain a competitive advantage and ensure their long-term success in the global marketplace.

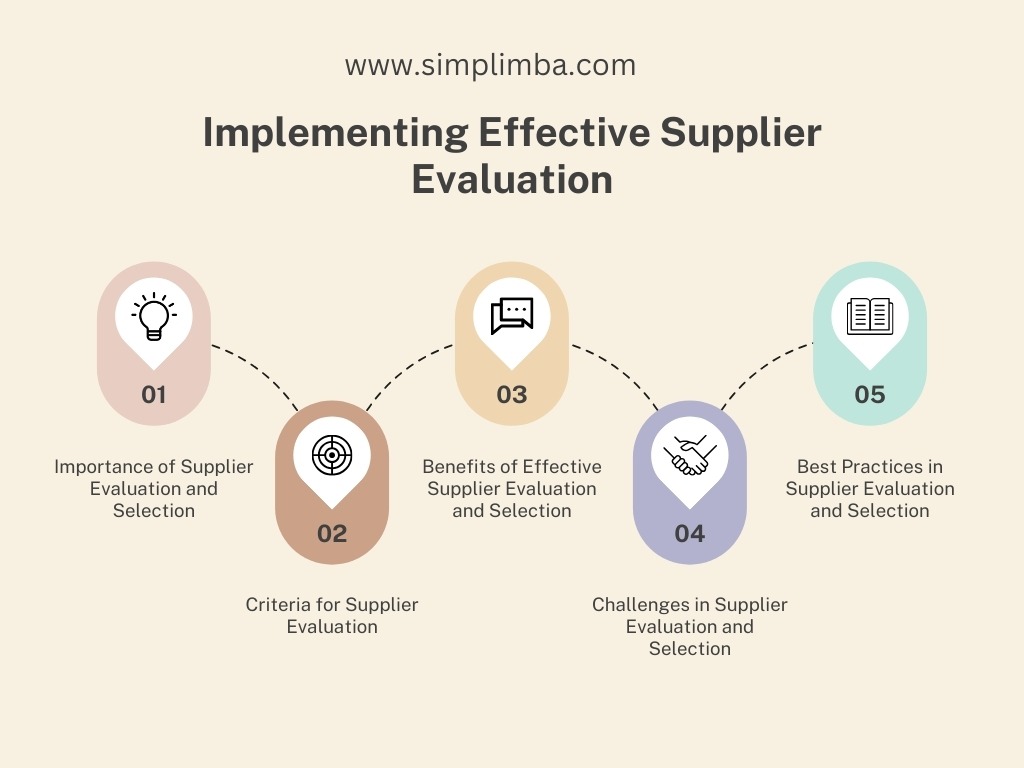

Implementing Effective Supplier Evaluation and Selection Processes

In today’s competitive business landscape, organizations must implement effective supplier evaluation and selection processes. The success of a company depends not only on its operations but also on the capabilities and reliability of its suppliers.

1. Importance of Supplier Evaluation and Selection:

Proper evaluation and selection of suppliers can have a significant impact on the overall performance and profitability of an organization. According to a study conducted by the Aberdeen Group, companies that have implemented supplier evaluation and selection processes have experienced a 17% reduction in supply chain costs and a 25% increase in on-time delivery performance.

2. Criteria for Supplier Evaluation:

When evaluating suppliers, organizations should consider various criteria, including quality, cost, flexibility, and reliability. It is essential to assess a supplier’s financial stability and capability to meet the organization’s specific requirements. A case study by Harvard Business Review found that companies that used a formal approach to evaluate suppliers and considered all relevant criteria experienced a 28% increase in overall supplier performance.

3. Benefits of Effective Supplier Evaluation and Selection:

Implementing an effective supplier evaluation and selection process can result in several benefits for an organization. These include improved product quality, reduced supply chain risks, increased customer satisfaction, and enhanced operational efficiency. According to a study by McKinsey, companies that adopt supplier evaluation and selection practices experience a 20% reduction in defects and a 30% decrease in lead times.

4. Challenges in Supplier Evaluation and Selection:

Despite the importance of supplier evaluation and selection, organizations face several challenges in implementing these processes. One common challenge is the lack of transparency in supplier performance data. Without access to accurate and relevant information, it becomes challenging to make informed decisions regarding supplier selection. A study by Deloitte found that 58% of organizations struggle to obtain reliable supplier performance data.

5. Best Practices in Supplier Evaluation and Selection:

To overcome the challenges associated with supplier evaluation and selection, organizations should follow best practices such as establishing clear evaluation criteria, conducting regular supplier performance reviews, and leveraging technology for data analysis. According to a survey by CAPS Research, organizations that adopted best practices in supplier evaluation and selection experienced a 16% reduction in supply chain costs and a 20% improvement in supplier performance.

Ensuring Supplier Performance and Quality in Supply base Management

Ensuring supplier performance and quality is crucial for businesses across industries. In today’s highly competitive market, companies need to maintain high standards to retain customers and stay ahead of the competition. Poor supplier performance and quality can lead to production delays, increased costs, and a negative impact on customer satisfaction.

One effective way to ensure supplier performance and quality is to establish clear and measurable performance metrics. By setting specific targets and regularly monitoring supplier performance against these metrics, companies can identify any deviations and take appropriate action. For instance, automotive giant Honda utilizes a stringent Quality Assurance System to measure supplier performance, with the goal of zero defects. This approach has helped Honda maintain high quality standards in its supply chain.

Another important aspect of ensuring supplier performance and quality is conducting thorough supplier audits. These audits involve assessing a supplier’s processes, capabilities, and overall performance. By conducting regular audits, companies can identify any potential issues and work with suppliers to address them. For example, Apple conducts frequent audits of its suppliers’ environmental practices to ensure compliance with its sustainability standards.

In addition to performance metrics and audits, effective communication is essential for ensuring supplier performance and quality. Companies need to maintain open and transparent lines of communication with their suppliers to address any issues promptly. This can involve regular meetings, feedback sessions, and performance reviews. For instance, Walmart holds regular supplier meetings to discuss performance issues and collaborate on improvement initiatives.

Lastly, developing strong relationships with suppliers is crucial for ensuring performance and quality. Companies that invest in building long-term partnerships with their suppliers are more likely to have better control over product quality and delivery performance. For example, Toyota has developed a close relationship with its key suppliers, enabling them to work collaboratively on continuous improvement initiatives and achieve high levels of quality.

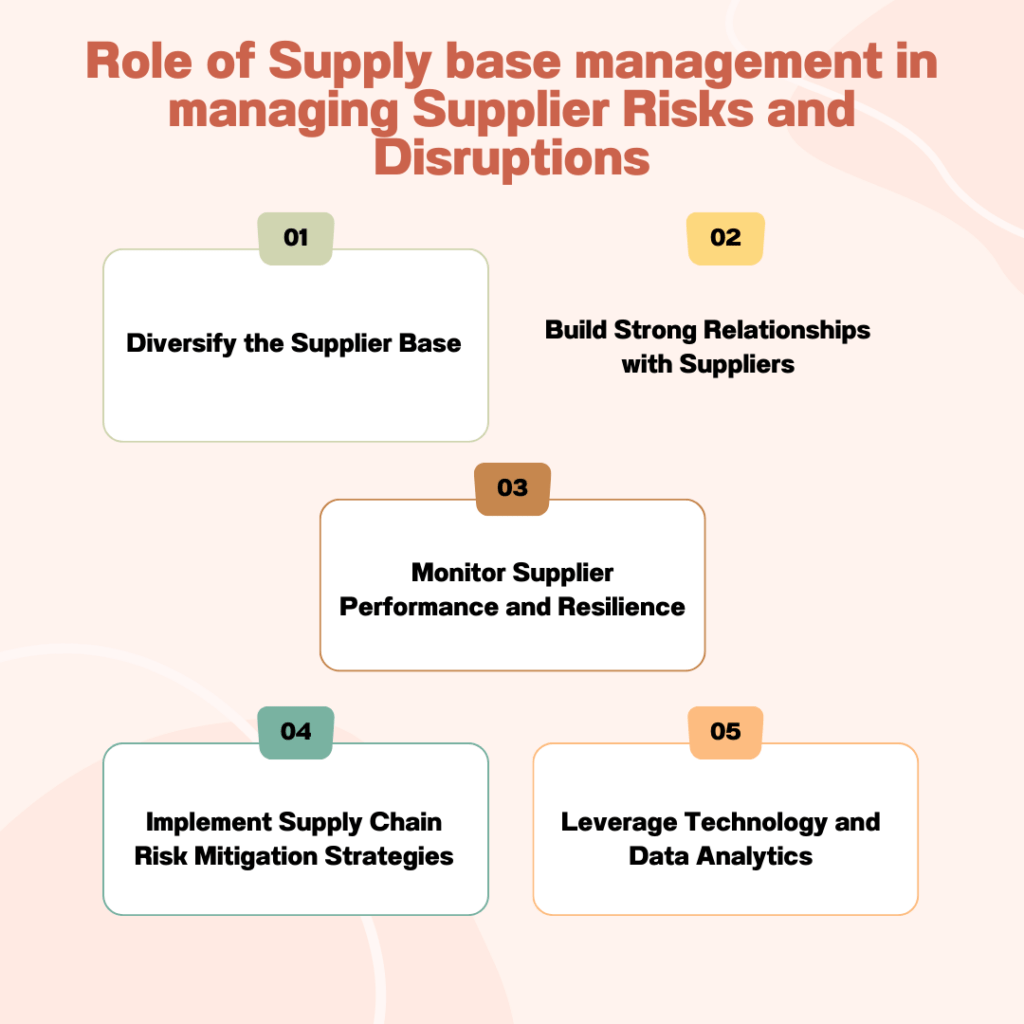

Role of Supply base management in managing Supplier Risks and Disruptions

In today’s fast-paced and interconnected global economy, managing supplier risks and disruptions is a critical task for businesses. The supply chain disruptions caused by events like natural disasters, geopolitical tensions, and global pandemics have the potential to severely impact an organization’s operations and profitability. Therefore, companies must implement effective strategies to mitigate these risks and ensure business continuity.

1. Diversify the Supplier Base: Relying on a single supplier can be risky, as any disruption in their operations can lead to significant supply chain disruptions for the company. By diversifying the supplier base, businesses can reduce their dependence on a single source and spread the risks. For example, during the 2011 earthquake and tsunami in Japan, many companies that relied heavily on Japanese suppliers experienced significant supply chain disruptions. In contrast, companies with diversified supplier bases were able to quickly shift their production to alternative sources and minimize the impact.

2. Build Strong Relationships with Suppliers: Developing strong relationships with suppliers is essential for effective risk management. By establishing open lines of communication and collaboration, businesses can gain better visibility into their suppliers’ operations and identify potential risks early on. For instance, in the case of the COVID-19 pandemic, companies with strong relationships with their suppliers were able to proactively address supply chain disruptions through effective communication and collaboration.

3. Monitor Supplier Performance and Resilience: Regularly monitoring supplier performance and resilience is crucial for identifying potential risks and taking proactive measures to mitigate them. Companies can use key performance indicators (KPIs) to evaluate supplier performance and assess their ability to handle disruptions. For example, tracking metrics such as on-time delivery, quality control, and financial stability can help identify potential risks and prompt necessary actions.

4. Implement Supply Chain Risk Mitigation Strategies: Companies should develop and implement robust supply chain risk mitigation strategies to minimize the impact of disruptions. This can include strategies such as dual sourcing, safety stock buffer, and agile manufacturing. By having alternative suppliers, maintaining buffer inventory, and adopting flexible manufacturing processes, businesses can better respond to unexpected disruptions and mitigate their effects.

5. Leverage Technology and Data Analytics: The use of technology and data analytics can significantly enhance supply chain risk management. Advanced analytics tools can help organizations identify potential risks, forecast demand, and optimize inventory levels. For example, by using predictive analytics, companies can improve their ability to forecast disruptions and take proactive measures to mitigate them. Additionally, technologies like blockchain can increase transparency and traceability in the supply chain, enabling better risk monitoring and management.

Creating a Sustainable Supply Base

Sustainable Supply Base Management is a critical challenge for businesses today. It involves developing a robust and reliable network of suppliers that can support the company’s long-term goals and objectives. Sustainability in the supply chain is not only important for environmental reasons but also for economic and social reasons.

1. Ensuring a sustainable supply base starts with selecting the right suppliers. Companies should evaluate potential suppliers based on their sustainability performance. For example, Patagonia, a leading outdoor clothing brand, implemented a rigorous supplier selection process that focuses on environmental, social, and labor issues. This approach has helped Patagonia build a sustainable supply chain and improve its overall brand reputation.

2. Another key aspect of creating a sustainable supply base is forging strong partnerships with suppliers. Companies should collaborate closely with their suppliers to align their sustainability goals and develop effective strategies to achieve them. For instance, H&M, the international fashion retailer, has implemented a supplier collaboration program called “Sustainability Incentive Framework” that encourages suppliers to reduce their environmental impact. This program has not only helped H&M improve its supply chain sustainability but also fostered innovation and resource efficiency in its supplier network.

3. Implementing transparency and traceability measures is crucial for ensuring a sustainable supply base. By having visibility into their supply chain, companies can identify potential risks and take proactive measures to address them. A notable example is the Palm Oil Transparency Toolkit developed by the World Wildlife Fund (WWF) and Unilever. This toolkit helps companies map their palm oil supply chain and identify any unsustainable practices. Through this initiative, Unilever has been able to achieve 100% traceability to the mill level in its palm oil supply chain.

4. Continuous monitoring and evaluation are essential components of a sustainable supply base. Companies should regularly assess their suppliers’ performance and provide feedback for improvement. This can be done through sustainability audits and scorecards. Walmart, for instance, conducts regular audits of its suppliers’ factories to ensure compliance with its sustainability standards. Through this process, Walmart has been able to address labor and environmental issues in its supply chain and improve the overall sustainability of its operations.

5. Investing in supplier development programs is another key strategy for creating a sustainable supply base. Companies should support their suppliers in adopting sustainable practices and provide them with the necessary resources and training. Nike, the global sportswear brand, has implemented a program called the “Nike Material Sustainability Index” to help its suppliers understand the environmental impact of their materials and make informed decisions. This program has not only helped Nike reduce its supply chain emissions but also empowered its suppliers to become more sustainable

Samrat is a Delhi-based MBA from the Indian Institute of Management. He is a Strategy, AI, and Marketing Enthusiast and passionately writes about core and emerging topics in Management studies. Reach out to his LinkedIn for a discussion or follow his Quora Page