Supplier selection criteria form the very basic procurement strategy. The criteria for supplier selection is a mission-critical task that falls under the purview of the purchasing function. This is especially important to keep in mind when we are discussing strategic components as well as bottleneck components. In neither of these groups is there any evidence to suggest who the suppliers are.

The long-term competitiveness of the supply chain will be directly impacted by a number of factors, including the quality of the suppliers and the integrity with which they were selected. The following is a possible breakdown of the steps involved in supplier selection criteria; however, this is in no way intended to be an exhaustive or all-encompassing list. The following are the procedures that should be followed when selecting the suppliers

Procedures for Supplier selection Criteria

Set up supplier selection criteria: Setting up supplier selection criteria is the most important procedure. Selection Criteria are generally a combination of two or many sub-criteria which include, quality, time of delivery, reputation, and so on. We will discuss in detail about these in the later part of the blog

Initial contact: Initial contact may be initiated from the supplier or from the purchasing team. Subsequent responses can form the base for procurement

Formal evaluation: Many organizations have a formal method of evaluation of a supplier and publicly available for discussion and evaluation. These forms criteria for supplier evaluation and selection which can be referred by the suppliers and can be allowed to enter the bidding process

Price quotation: It is one of the most primitive forms of supplier selection criteria that is used to date. The assessment of the supplier is solely dependent on the price it offers to the purchasing team. Before empaneling a supplier, generally, an RFQ- Request for Quotation is floated across many similar suppliers and generally, the lowest quote is selected

Financial data: The financial data of the supplier is a key for supplier selection criteria. Whether the supplier will be able to make substantial capital and revenue expenses for the business or will invest money in expanding the business is generally assessed before selecting a supplier

Reference checking: References of previous purchasing offices are taken before assessing a supplier

Supplier visit: Supplier visits are generally planned before the assessment to physically check the facilities and competencies of the supplier. Many organizations follow this method to find non-conformances of a supplier and give them adequate time to resolution before awarding final business

Audits, assessments, or surveys: Audits and surveys are not very different supplier assessments. However, audits and surveys have long-term continuity and improvement plans attached to them.

Supplier Selection Criteria : Methodologies

It would appear that the primary focus of these processes is on defining the criteria and determining how to evaluate them. However, there are three ways that are rather distinct from one another regarding the choice of suppliers.

Quantity of Supply

The first consideration is the quantity of the product that can be supplied by the vendor. This strategy will generally involve testing the product prototype to determine whether or not the quality and technical criteria can be reached, as well as whether or not the delivery terms are suitable.

Competencies of the Supplier

The second factor is determined by the capabilities that are shown by the provider. It typically determines whether or not the provider possesses the potential for design and development, strategic investment in technology and talents, and management that is up to scratch. This capability-based approach is frequently utilized for long-term supplier selection, and the process can be initiated well before the concept of the component is beginning to take form.

Combination of two techniques

The combination of the selection of products and capabilities is the third option. It is applicable in the event that a strategically significant new part is going to be procured from a different supplier. In order to maintain the growth of the supply chain, the supplier must not only meet all of the needs that are unique to the product, but they also need to be able to produce newer generations of the product in the long run. The following are some examples of widely applied criteria for capacity filtering

Assessment criteria on the supplier’s capability:

- Total quality management policy

- BS 5750/ ISO 9000 certification or equivalent

- Implementing the latest techniques e.g. JIT, EDI

- In-house design capability

- Ability to supply locally or worldwide as appropriate

- Consistent delivery performance, service standards, and product quality

- Attitude on total acquisition cost

- Willingness to change, the flexible attitude of management and the workforce

- Favorable long-term investment plan

Supplier selection criteria: Quantitative Methodology

Utilizing quantitative techniques is helpful in terms of making the process of selecting a supplier easier. They can help make the selection criteria more sensible; they can serve as the platform for meaningful discussion or debate; they can give traceable documentation, and they may form the factual contents for decision-making. This article presents three fundamental quantitative tools for managers so they can get a head start on developing their own tools tailored to their own industry and goods.

We will narrate supplier selection criteria examples of 3 Suppliers A, B, and C with various competencies and expected results for quality and deliveries.

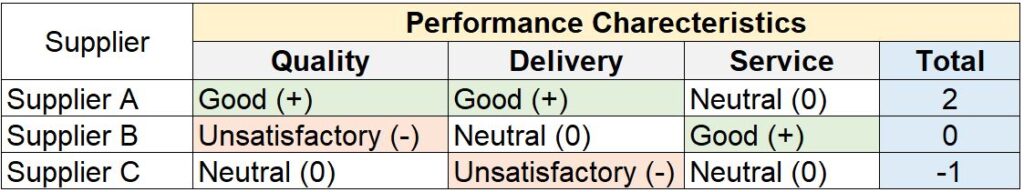

Supplier selection criteria: Categorial Method

The first one is referred to as the “categorical Method,” and it is displayed in the figure below. After determining the selection criteria, which might include things like quality, delivery, and customer service, you give each potential provider a score based on three different categories: “good” (+), “unsatisfactory” (-), and “neutral” (0). The final step is to add up each potential provider’s category scores to arrive at a total score; the provider with the highest score will be chosen. The application of this strategy couldn’t be easier, although it is somewhat subjective. As a result, it is recommended that a multi-functional team be formed in order to make collective decisions in order to reduce the amount of prejudice that comes from individuals.

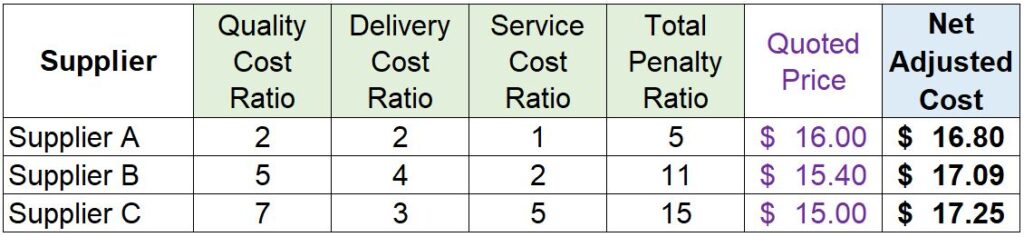

Supplier selection criteria: Cost Ratio Method

The second approach, which can be seen illustrated in the figure below, is referred to as the “cost ratio method.” In a similar manner, you establish the necessary criteria in comparison to the other vendors. The method differs from the categorical method in that it does not just rely on the subjective opinions of the participants in the study. It does this by utilizing some of the data that is already available on the quality performance, such as the service standard and delivery reliability, for example. Using the data that has been gathered throughout time, you will be able to determine the cost ratios that correlate to each criterion in terms of how much of an additional cost should be incurred as a result of failing to meet that requirement.

After that, the initial unit prices that were quoted by the various suppliers will be readjusted so that the net-adjusted costs may be calculated. It is then made abundantly evident that if the decision of the provider is to be based on the initial quoted unit price, then supplier C ought to be chosen because its cost is the most economical.

However, if the process of selecting a supplier takes into consideration the historical performances of the provider in each of the three areas and uses the net-adjusted cost, then the supplier with the lowest cost is A and not C. A small bit of research into weighing the benefits against the costs led to completely different decisions being made during the choosing process.

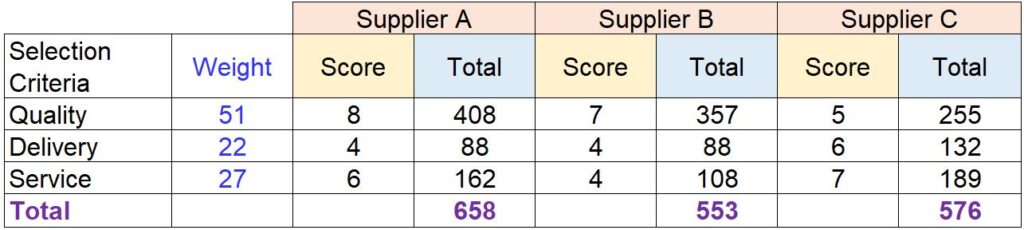

Supplier selection criteria: Linear Average Method

The fact that all of the factors are given equal weight in the decision-making process is one of the shortcomings of both of the aforementioned approaches. In the real world of business, this is not at all the case. People have diverse inclinations for various criteria for a variety of different reasons. In certain contexts, meeting quality expectations is more essential than meeting delivery deadlines, whereas in other contexts, meeting delivery deadlines is more essential than meeting quality expectations.

The third approach takes into account these preferences by giving a certain amount of weight to each of the criteria. As depicted in the table, this technique is referred to as the “linear-average method.” The weight is a score that represents how important the criterion is in comparison to the other factors. In most cases, the total number of weight scores adds up to 100.

After multiplying the judgment score by the weight, you will get the adjusted judgment score. After that, you will add together all of the adjusted scores to get the total selection criteria (score) for the provider. It is important to keep in mind that the weight can be utilized not only with the cost ratio approach but also in any other way. In the end, the most appropriate technique for selecting suppliers is probably a combination of a few of those different methods.

Though we have selected three criteria – Quality, Delivery, and Service for our assessment, you can consider many others like technical competency, time to delivery, other associations, feedback from other procurement teams, previous track records, and so on. We also have to ensure that these are quantifiable and recordable as we have done here.

Samrat is a Delhi-based MBA from the Indian Institute of Management. He is a Strategy, AI, and Marketing Enthusiast and passionately writes about core and emerging topics in Management studies. Reach out to his LinkedIn for a discussion or follow his Quora Page