What is Kraljic Matrix or Krajlic Purchasing Portfolio Matrix?

“What is the most effective method for buying management?” “What is the most effective tactic for buying and getting supplies?” These are questions that have been asked in the past by a large number of practitioners as well as academics, and they continue to be asked today. In point of fact, there was no lack of solutions to these queries in any of the numerous kinds of literature that existed even in the early years of the subject.

But very few of them could withstand the test of time in terms of their application and universality. Then along came Dr. Peter Kraljic from McKinsey, who asserted that there is no one method that is superior to all others when it comes to the management of purchasing in all contexts. After that, in September 1983, he submitted an article to the Harvard Business Review titled “Purchasing Must Become Supply Management,” in which he suggested the Kraljic Purchasing Portfolio model or Kraljic Matrix, which is pretty well known today.

Since that time, this model has received extensive citations and references all around the world in a variety of different management literature. There are currently several different versions that have been updated by a large number of academics, all of whom have contributed to and further refined the use of this model.

The response that Dr. Kraljic provided to the question can be paraphrased as follows: “although there is no single best way, if we know which product category we are purchasing, there would be the best way to do the purchasing for this product category.”

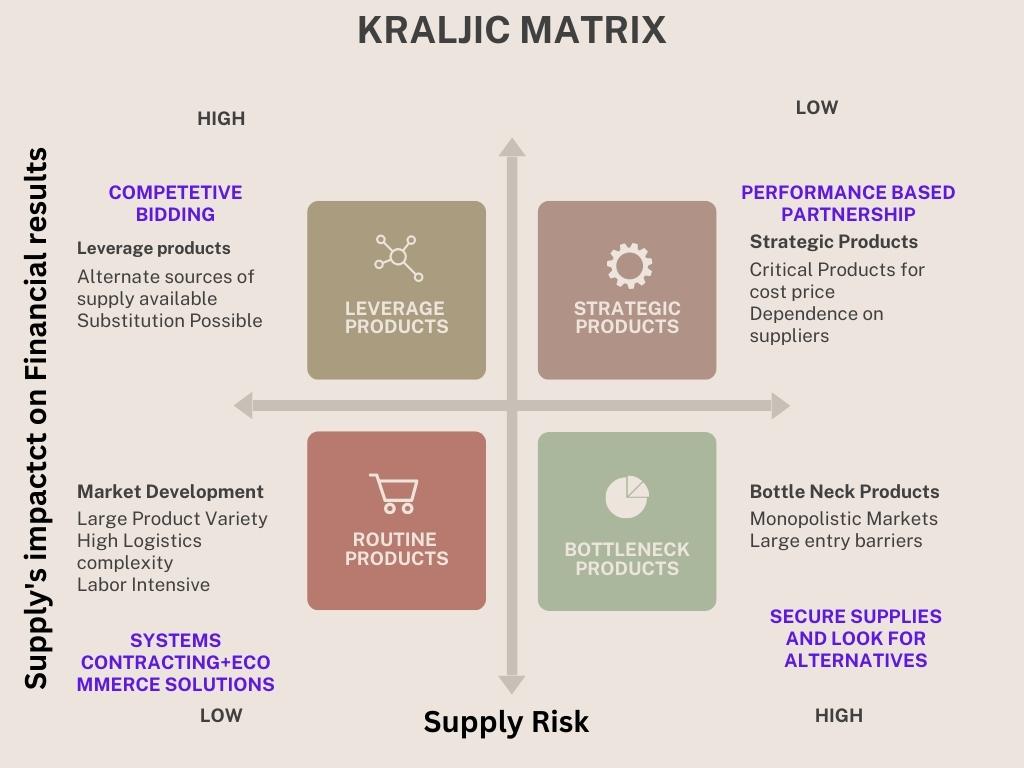

This is Dr. Kraljic’s explanation of why there isn’t a single best way. In order to classify all of the items that had been purchased, he used a two-dimensional approach. The first is the possibility that the market will run out of the product, and the second is the effect that the item will have on one’s finances. As a result, a matrix with four categories came into being, each of which presented a unique kind of goods that could be bought.

What is Kraljic Matrix Used For?

Kraljic Matrix is a widely accepted tool for determining your purchasing portfolio mix. It is composed of 4 quadrants and compares two parameters

- Supply Risk

- Supply’s impact on financial risk

Kraljic matrix is widely used in assessing and categorizing supplies and what strategy needs to be incorporated in order to get the best out of these circumstances

What are the four 4 key quadrants in the Kraljic matrix?

The Four Key Quadrants in Kraljic Matrix Are

Leverage Products: Products for which alternate sourcing and substitution are possible

Routing Products: Products that have a large product variety and have large logistical complexity

Strategic Products: Products that give competitive advantages to an organization

Bottleneck Products: These products have larger barriers to entry and generally have a monopolistic market

What are the various components of the Kraljic Matrix?

Leverage Products

Leverage products are those that you acquire from your supplier that will have a large impact on the financing of your own end product, but it is reasonably easy to obtain from the supply market, thus there is low market risk associated with doing so. For instance, a manufacturer of wood furniture should consider purchasing wood because it is a leveraged product.

This is due to the fact that the vast majority of the furniture they produce is constructed out of wood. The price of wood accounts for a significant amount of the total cost, and the price of furniture is directly related to the price of wood on the open market. On the other hand, unless it is a rare wood that they hardly ever use, there is an abundant supply of wood, and there is a very low probability that there will be a short supply.

Kraljic matrix recommends using the approach of competitive bidding when purchasing leverage items of this kind. It should come as no surprise that for competitive bidding to be successful, there must be more than one provider.

This strategy is supported by the minimal supply risk element associated with leverage goods. In this particular scenario, there are a number of potential alternate suppliers, and switching suppliers is an option. The purchaser will then be able to take advantage of the lower price and the cost savings. Because leveraged items have such a substantial influence on a buyer’s finances, it is essential that they be aware of the necessity of taking these steps.

Routine Products

The materials that fall into the category of “routine products” are those that have a negligible effect, monetarily speaking, on the purchaser’s own products and from which there is a large selection available on the market.

Small fixtures, pants, and common components such as springs and nuts are some examples of the goods or materials that fall into this category. When weighed against the whole cost of producing your own goods, their prices are rather low. The availability of such commodities on the market is extremely high, and there is no danger of a shortage occurring.

Kraljic matrix offers a purchasing strategy for routine products that included system contracting in addition to e-commerce solutions. This is because the routine products have a great variety of options, a high level of logistical complexity, and frequently require a lot of manual labor to handle. Ordering is handled via an advanced computer-based system, which is a good fit given the nature of the items.

Although there are other potential sources of supplies accessible, it is not recommended that you place a bid. This is due to the fact that the low cost of the materials made it unnecessary to have a bidding process, and the diversity and complexity of the materials will make it unaffordable to hold a bidding process.

Strategic Products

The products that are considered strategic are those that have a significant level of the financial impact on the final product. They are extremely expensive to develop and build, and they frequently require components that demand high levels of technology. They are typically not offered for sale elsewhere, which results in a significant supply risk. Instead of paying for delivery, the buyer will be responsible for negotiating the terms of the production contract. These products include, for instance, engines for automobiles and compressors for refrigerators.

Kraljic matrix suggested using a purchasing strategy that was a performance-based partnership for the things that were strategic. That entails forming a collaborative relationship with the manufacturer so that both parties may work together on the design and production of the component parts. The suggestion is unquestionably based on sound reasoning. It is typical for these kinds of components not to be made in sufficient quantities to be kept in stock.

Instead, they must be ordered in accordance with the exact requirements, and in many cases, the components will need to be designed and produced in collaboration with the provider. Therefore, in the strictest sense, it is no longer the purchasing of items; rather, it is the purchasing from the suppliers of the capacities for designing and making products. Because of this, having a system that is “performance-based” is essential, as the focus should be on capabilities.

Bottleneck Products

Bottleneck products are those components that may or may not cost too much in contrast with the total material cost, but they must have them, and it is very difficult to get a hold of them. Bottleneck products are also known as “critical components.” The availability of those components is not guaranteed, and there is a high risk associated with the supply chain for those components. One example of a common bottleneck material is the very little quantity of precious metal that is required for the exhaust purification system.

If it does not have it, the vehicle will not meet the required environmental standard and will not be permitted to be driven on the road. There are only a very small number of supplies in the globe that have the natural resource that can produce those valuable metals, and those supplies are extremely scarce. The gap between supply and demand is extremely wide.

When it came to the purchase of such bottleneck products, the Kraljic matrix suggested an approach that included both securing the supply and looking for alternatives. You have no choice but to make sure you have enough of your present supply because you need it, but you also need to look for other options because there is always the possibility of cutthroat competition.

The alternatives consist of radical new designs, some of which might use different materials that are readily available in sufficient quantities. In this type of partnership setup, the supplier has the upper hand, while purchasers will need to make some adjustments to their plans.

Samrat is a Delhi-based MBA from the Indian Institute of Management. He is a Strategy, AI, and Marketing Enthusiast and passionately writes about core and emerging topics in Management studies. Reach out to his LinkedIn for a discussion or follow his Quora Page